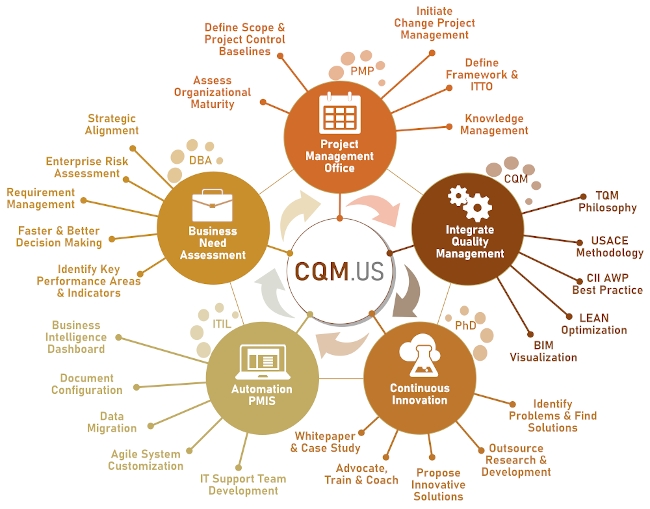

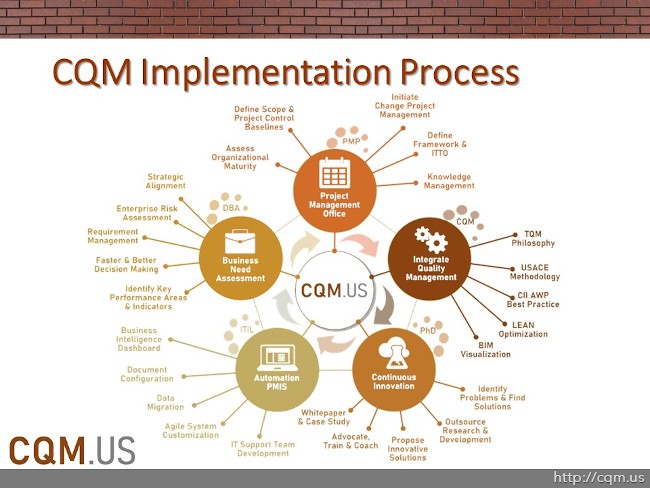

The CQM experts, through CQM.US, aim to provide comprehensive Construction Project Management Professional Solutions. This is achieved through Project Management Services designed to identify, administer, and manage Business Case Needs and Requirements, leading to successful CQM Implementation via a proven CQM Methodology. A successful CQM Implementation plan integrates several key areas and progresses through distinct phases, drawing on established Project Management Institute (PMI) principles and practices.

CQM Implementation Plan

A successful CQM Implementation plan includes, but is not limited to:

- Integrated Quality Management

Integrated Quality Management within CQM focuses on overseeing all activities and tasks required to maintain a desired level of quality, encompassing quality planning, quality assurance, and quality control. This holistic approach emphasizes building quality into processes and deliverables from the outset to avoid costly rework later in the project lifecycle. It involves clearly identifying quality requirements and standards for the project and its deliverables, outlining how compliance will be demonstrated, and ensuring these objectives are understood across all project components. Tools like Earned Value Management (EVM) are crucial for integrating scope, schedule, and resources, objectively measuring performance, and forecasting project outcomes, particularly for quality and risk impacts. Furthermore, Configuration Management (CM) processes are applied to manage configuration items, ensuring that only approved changes are incorporated and maintaining traceability and version control for all deliverables. - Strategic Alignment Management

Strategic Alignment Management ensures that CQM.US is presented as a critical enabler for organizations to achieve their strategic goals and objectives, and that investments in projects lead to clear, sustainable benefits. This approach bridges the “strategy-to-implementation gap” by ensuring that project work is effective and purposefully aligned with overarching organizational goals. PMI frameworks for portfolio, program, and project management are leveraged as integral components of strategy execution. The business case is a fundamental document that drives project scope, justifies investments, and outlines the expected value contribution, whether qualitative or quantitative. Ultimately, robust quality management contributes to strategic goals and sustained competitive advantage by improving overall performance and organizational agility in response to market changes. - Business Requirement Management

Business Requirement Management involves establishing requirements baselines, maintaining traceability, and managing change to ensure project success. This includes tasks such as eliciting, analyzing, documenting, and validating requirements. A key aspect is linking requirements to Conditions of Satisfaction (CoS), which are measurable commitments that define “success” for the project team, addressing objectives like budget, schedule, safety, profitability, delivery time, and quality metrics. Active stakeholder involvement is paramount in the discovery and decomposition of needs into requirements, as the success of a project is directly influenced by the care taken in determining, documenting, and managing these requirements. These requirements become the foundation of the Work Breakdown Structure (WBS), on which cost, schedule, quality planning, and procurement are based. - Organizational Maturity Assessment

Organizational Maturity Assessment uses tools like Organizational Project Management (OPM) maturity models to measure an organization’s adoption and consistent implementation of recommended project management practices. This includes frameworks like the Construction Industry Institute (CII) Interface Management (IM) maturity model, which guides structured IM implementation for built environment projects. The assessment involves evaluating the current state of governance and project management capabilities, defining a vision for the future state, and identifying gaps, often in preparation for change initiatives. The outcome informs how methodologies should be tailored to the specific organizational culture, types of projects, and strategic objectives, recognizing that a “one-size-fits-all” approach is rarely effective. - Transition & Change Management

Transition and Change Management is a comprehensive, cyclic, and structured approach for transitioning individuals, groups, and organizations from a current state to a future state with intended business benefits. This critical capability is embedded in PMI’s project and program management standards, particularly within stakeholder management, communications management, risk management, and governance. The process typically involves iterative phases: Formulate, Plan, Implement, Manage Transition, and Sustain Change. Effective stakeholder engagement and communication are crucial throughout, ensuring that stakeholders are informed of objectives, actively participate, and that potential resistance to change is addressed. A well-defined transition plan is essential to integrate project outputs into ongoing operations and ensure the sustainment of intended benefits. - Business Intelligence Solutions

Business Intelligence Solutions leverage Project Management Information Systems (PMIS) and Business Intelligence (BI) dashboards to provide real-time visibility and timely insights for decision-making regarding baseline data and early warning indicators of potential risks. These systems facilitate efficient documentation, data capture, and reporting of risk-related and performance information. Advanced technologies such as Building Information Modeling (BIM) and Digital Twins are vital for virtual risk simulation and constructability reviews, allowing early identification and resolution of conflicts and quality issues before physical construction begins. The integration of IoT, field applications, AI, and Big Data analytics enables predictive risk alerts and enhanced project monitoring of physical resources and work performance, supporting data-driven decision making. - Implementation Phases

The above implementation plan will go through the following phases:- Need Assessment & Gap Analysis

This phase involves conducting Needs Assessment to identify and define current business problems or opportunities, typically pre-program and pre-project, ensuring that previously made decisions remain valid in evolving circumstances. It encompasses defining the current state of quality management, identifying gaps against a desired future state, and linking these to the organization’s mission, vision, and strategic goals. Techniques such as SWOT analysis can be employed to understand high-level views surrounding a business need. The ultimate goal is to generate a high-level needs definition that informs viable solution options and drives the development of a robust business case. - Proposal & Charter for Change Management

Following needs assessment, this phase focuses on developing a project charter, which formally authorizes the existence of a project and provides the project manager with the authority to apply organizational resources to project activities. The business case, developed during the needs assessment, serves as a major input to the charter, outlining project objectives, required investment, and financial and qualitative criteria for project success. Concurrently, change management plans are formulated, detailing how change requests throughout the project will be formally authorized and incorporated. The project charter may also incorporate Conditions of Satisfaction (CoS), codifying the definition of “success” and mutually negotiated commitments among team members. - Training & Lunch+Learn Sessions

This phase is dedicated to developing talent and capabilities by identifying and addressing skill gaps through upskilling and reskilling the workforce. It includes providing formal training for project stakeholders to understand the need, requirements, development, and maintenance of CQM plans and related activities. Training aims to improve the competencies and capabilities of stakeholders to effectively interact with and utilize systems like the Earned Value Management System (EVMS). These sessions also facilitate active listening and two-way communication to understand diverse perspectives and potential resistance to change. - PMO for Process & Procedure Improvement

The Project Management Office (PMO) plays a vital role in this phase by standardizing and optimizing quality-related governance processes, methodologies, tools, and techniques across projects, promoting efficiency and continuous improvement. PMOs are instrumental in driving continuous improvement initiatives, often utilizing methods such as the Plan-Do-Check-Act (PDCA) cycle. They develop and maintain robust governance frameworks, ensuring that CQM practices are aligned with strategic objectives and facilitate key decisions. Additionally, the PMO fosters talent and serves as a central hub for knowledge management, facilitating the capture, archiving, and dissemination of lessons learned and best practices related to quality, thus contributing to organizational learning. The establishment and documentation of formal work processes and procedures are critical to ensure consistent, reliable, high-quality work and to prevent loss of configuration control. - Coaching & Implementation of Changes

This phase involves the practical execution of new or enhanced CQM functions, processes, and procedures that were planned. It is an iterative process, where plans are continually monitored, adjusted, and reworked to optimize intended outcomes. Coaching and leadership are essential to influence the adoption of new quality capabilities and ensure benefits sustainment, addressing challenges like resource limitations and resistance to change. Configuration Change Management (CCM) processes are rigorously applied to manage changes to configuration items, ensuring that only approved changes are incorporated into deliverables and that their impact is systematically evaluated. Continuous monitoring and measurement of acceptance, adoption rates, and benefits realization are performed to ensure the change is effectively integrated and delivers the intended value.

- Need Assessment & Gap Analysis

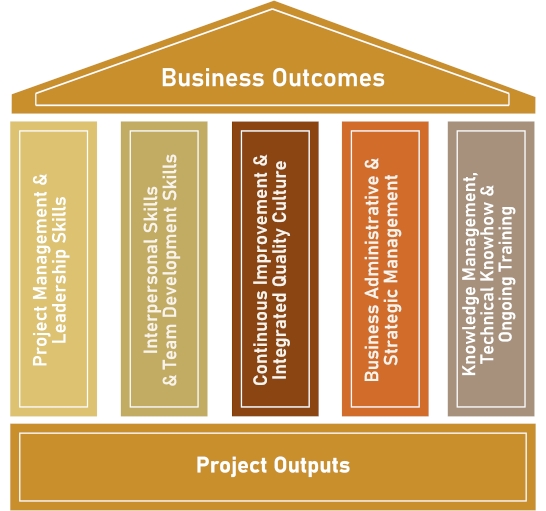

QualityPMO for CQM Solutions

The Enterprise-Level PMO for Business Outcome Delivery section outlines how an organization can achieve strategic business outcomes through a sophisticated, system-thinking approach to quality management, led by an Enterprise Project Management Office (EPMO). This framework recognizes that while construction projects are unique and complex, they benefit from adaptable, principle-based methodologies, rather than a single, prescriptive “Construction PMO methodology”.

Strategic Business Outcome Focus with QualityPMO Methodology

The ultimate goal of Integrated Quality Management (CQM), anchored in a “QualityPMO methodology for System Thinking,” is to provide strategic solutions for businesses. This enables organizations to make informed decisions on their Quality Management needs without compromising their Core Business Objectives, while simultaneously accelerating project outputs to achieve aligned strategic business outcomes. This approach views the organization as a complex adaptive system, focusing on continuous value creation and sustained competitive advantage by effectively implementing strategy through programs and projects. The “QualityPMO methodology for System Thinking” leverages the comprehensive, cyclic, and structured approach for transitioning individuals, groups, and organizations from a current state to a future state with intended business benefits.

Business Needs Assessment for Strategic Alignment (EPMO-Led)

An Enterprise-level PMO (EPMO), utilizing this QualityPMO methodology, performs a comprehensive Business Need Assessment. This assessment goes beyond merely defining project outputs; it focuses on understanding and achieving measurable business value and strategic objectives. It is crucial for bridging the “strategy-to-implementation gap” by ensuring that all actions are purposefully aligned with overarching goals. The EPMO defines business problems or opportunities and explicitly links them to the organization’s goals, vision, and strategic objectives. This process helps identify capability gaps and viable solution options that provide continuous value to the organization. This structured, analytical approach is akin to applying advanced business analysis skills, often encompassing the “Define Problems & Find Solutions” stage where profound insights and solutions emerge.

The key aspects of this EPMO-led assessment include:

- Strategic Alignment: This ensures that all quality management initiatives are directly linked to the organization’s overarching strategic objectives and vision, delivering anticipated benefits and value. It involves understanding the current state, defining the desired future state, and detailing how quality initiatives will bridge this gap.

- Enterprise Risk Assessment: The EPMO conducts a thorough Enterprise Risk Assessment by identifying, analyzing, and prioritizing risks across portfolios, programs, and projects within an Enterprise Risk Management (ERM) context. This process evaluates both threats and opportunities, considering their impact on business objectives, and developing appropriate responses to facilitate informed business choices and proactively mitigate risks.

- Requirements Management: This focuses on eliciting, analyzing, and documenting high-level business requirements that support strategic objectives and align with the business case. The goal is to ensure that proposed solutions effectively address identified business problems or opportunities and meet stakeholder expectations.

- Key Result Area Identification (Benefits Realization): This involves defining and measuring specific, measurable, achievable, relevant, and time-bound (SMART) benefits that align with organizational objectives, focusing on the ultimate value realized from quality initiatives. This includes tracking benefits realization beyond project completion, ensuring that the return on investment is verified through operational use.

Organizational Project Management Maturity & CQM Implementation (EPMO-Led)

CQM Implementation efforts are managed as strategic initiatives, often structured as programs, by an Enterprise-level PMO (EPMO). This EPMO is responsible for aligning program and project work with organizational strategy, establishing appropriate enterprise governance, and performing portfolio management functions to ensure strategy alignment and benefits realization. It adopts a system-thinking approach to navigate the complexities inherent in organizational change, which is essential for implementing an Integrated Construction Quality Management System.

The EPMO, comprising Project Management Professionals (PMP) from diverse disciplines (Construction, Engineering, Business, Information Technology, Risk Management), ensures a common language and integrated understanding when dealing with organizational change management. The traditional absence of a single, named “Construction PMO methodology” in the industry underscores the necessity of tailoring PMI’s comprehensive frameworks to the unique context of construction projects, organizational culture, and specific needs. The CQM Methodology, deeply rooted in the QualityPMO’s System Thinking approach, emphasizes this adaptive strategy to accelerate project outputs that are precisely aligned with strategic business outcomes.

The EPMO-led implementation proceeds through iterative and integrated steps:

- Assess Organization Maturity & Readiness for Change: This step involves evaluating the organization’s current state of project management maturity, existing Quality Management Systems (QMS), capabilities, processes, and tools against industry best practices and the desired future state. A crucial part of this assessment is evaluating the organization’s capacity and culture to absorb change, identifying potential resistance, and determining the optimal pace for transformation.

- Review Organization Knowledge Assets (OPAs): The EPMO systematically collects, organizes, and analyzes existing knowledge assets, including lessons learned, historical performance data, and established processes and procedures. This foundational work supports continuous improvement, organizational learning, and effective knowledge transfer across the enterprise.

- Define Scope & Start Planning, Benchmarking: Clearly define the scope of the CQM implementation, linking it directly to the assessed business needs and strategic objectives. This includes developing a detailed plan that integrates quality, cost, schedule, risk, and communications. Benchmarking against industry standards and best practices helps in formulating viable options and setting realistic performance targets for the organization’s digital maturity and capabilities.

- Continuous Monitoring & Control: Implement robust mechanisms for the ongoing monitoring of quality performance, adherence to defined processes, and progress against Key Performance Indicators (KPIs) and established baselines. This includes diligent configuration management for all approved changes, ensuring traceability, version control, and audit trails for all relevant documentation and deliverables. Earned Value Management (EVM) principles are applied to objectively measure performance and forecast outcomes, even at program and portfolio levels, providing critical insights into the value generated from resource utilization.

- Change Management: Actively manage the transition from the current organizational state to the desired future state, involving stakeholders at all levels. This iterative process, encompassing formulation, planning, implementation, and continuous improvement, requires strong leadership support and transparent communication to foster buy-in and address resistance to change effectively. It further involves providing sufficient resources (time, people, and budget) to support and reinforce project deliverables, including process design, organizational design, policy or procedure development, and culture change, to ensure sustainable adoption and benefits realization.

To address the specific needs related to contractor assurance and contract management in complex environments, the EPMO’s functions would also integrate:

- Robust Governance for Contracts: Establishing and maintaining comprehensive governance frameworks for contract changes, ensuring adherence to procurement procedures, and managing agreements with third-party vendors.

- Proactive Interface Management: Employing tools and processes, such as the Project Interface Risk Impact (PIRI) matrix and the Interface Complexity Assessment Tool (ICAT), to proactively assess and manage cross-disciplinary coordination and risks associated with internal and external interfaces, particularly with contractors.

- Integrated Configuration Management: Ensuring that all contractual documents, project outputs, and deliverables conform to approved changes, maintaining strict traceability, version control, and audit trails throughout the project lifecycle.

- Strategic Risk Management for Contracts: Actively identifying, analyzing, and developing response strategies for risks specifically associated with contracts and external parties, ensuring these are integrated into the overall enterprise risk management framework.

- Comprehensive Stakeholder Engagement with Contractors: Engaging external stakeholders, including contractors and suppliers, as early as possible and throughout the project life cycle to facilitate buy-in, improve robustness, and increase the potential for successful benefits realization from changes.

Integrated Quality Management Requirements and Implementation Steps

The Integrated Quality Management aspect of CQM Implementation is a comprehensive approach that ensures quality is a continuous, embedded, and strategically aligned component of construction projects. The Project Management Team, collaborating with Business Administrators, provides crucial inputs for Construction Quality Management (CQM) requirements, drawing on CQM Methodology and necessary skill sets. This integrated effort is designed to drive successful outcomes through a structured, multi-phase process.

The Integrated Quality Management Team leads several key steps to ensure effective CQM implementation:

- Existing QMS Assessment

This initial step involves evaluating the current state of quality management within an organization. It aims to understand the organization’s existing capabilities, processes, and tools related to quality. This assessment helps identify current strengths and weaknesses, forming the basis for subsequent improvements. It also helps in understanding the organization’s readiness for change in its quality management practices. - Gap Analysis Compared to Best Practices

Following the assessment, a gap analysis is performed to compare the current state of quality management against a desired future state and industry best practices. This process involves identifying discrepancies and opportunities for improvement in relation to standardized practices and methodologies, such as those recommended by PMI. The goal is to define the necessary changes to achieve higher quality standards, ensuring that the implementation is tailored to the specific organizational culture, types of projects, and strategic objectives, rather than a “one-size-fits-all” approach. This informs the development of an effective CQM framework. - Innovation & Technology Reviews

This step focuses on leveraging modern technologies to enhance CQM efficiency and effectiveness. It involves reviewing and adopting key digital technologies that align with the organization’s strategic goals and project needs. Key technologies include:- Building Information Modeling (BIM) and Digital Twin tools: Essential for virtual risk simulation and constructability reviews, enabling early identification and resolution of potential conflicts and quality issues before physical construction. BIM also supports early input and refinement of project scope and evaluation of change impacts.

- Project Management Information Systems (PMIS) and Business Intelligence (BI) dashboards: Provide real-time visibility and timely insights for decision-making regarding baseline data and early warning indicators of potential risks.

- Internet of Things (IoT), field applications, Artificial Intelligence (AI), and Big Data analytics: Enable predictive risk alerts and enhanced project monitoring of physical resources and work performance, supporting data-driven decision making.

The review also considers the interoperability of different technology platforms to ensure seamless data flow, especially for predictive analytics and AI solutions that require large data sources.

- Integrate Quality Services Solution

This involves a holistic approach to Quality Management (QM), defining it as the oversight of all activities and tasks necessary to maintain a desired level of quality, encompassing quality planning, quality assurance, and quality control. The solution emphasizes building quality into processes and deliverables from the outset, particularly during the design phase, to prevent costly rework later. It establishes clear quality objectives, requirements, and standards for all project deliverables, detailing how compliance will be demonstrated and ensuring these objectives are understood across all project components. This integrated approach aligns quality management with other project management plans, such as scope, schedule, cost, risk, communications, resource, procurement, and stakeholder engagement, forming a cohesive strategy for project delivery. - Customized CQM Implementation

CQM implementation must be tailored to the specific context of the organization and project. This involves deliberately adapting the approach, governance, processes, tools, and methodologies to suit the given environment and the work at hand. The objective is to maximize value, manage constraints, and improve performance by utilizing “just enough” processes, methods, templates, and artifacts to achieve the desired outcomes, recognizing that a generic solution is often ineffective. - Define Problems & Find Solutions (“Magic” happens)

This phase is crucial for identifying and addressing core challenges. It begins with Needs Assessment, which defines business problems or opportunities and links them to organizational goals, vision, and strategic objectives. This is where various expertises converge to define problems, research, and develop the best solutions. Business analysis skills are essential for eliciting stakeholder needs, analyzing current and future states, and recommending viable solution options that align with business objectives and provide continuous value. Techniques such as Value Management/Value Engineering are integrated to optimize project life cycle costs, improve quality, and identify gaps or opportunities for improvement by analyzing established baselines and developing alternatives. Active stakeholder involvement is paramount in understanding the true nature of problems and gaining consensus on solutions, ensuring acceptance and maximizing benefits. This involves a continuous learning process, akin to academic research, to evolve solutions and approaches. - Develop Systems and Tools

Upon approval from top management, the implementation proceeds with the selection of an Automation PMIS system. This system is configured to capture and manage data from various project management processes on a single, web-enabled platform. Key Performance Indicators (KPIs) are identified and integrated to facilitate Business Intelligence (BI) data collection automation, providing insights and generating reports on dashboards for timely decision support. The Information and Communication Technology (ICT) team and BI developers provide full support, continuously improving these systems and tools in collaboration with the Project Management Professional (PMP) and CQM teams. Rigorous configuration management mechanisms are put in place to ensure that all documents (e.g., interface documents, procedures, design documents) are systematically updated, maintaining version control and audit trails, preventing loss of configuration control, and ensuring traceability.

CQM Business Implementation

The CQM Methodology is most effective when it is aligned with the organization’s Business Strategies. This strategic alignment ensures that all quality initiatives contribute directly to overarching organizational goals and the realization of intended benefits.

Implementation is best facilitated through a Quality Project Management Office (QPMO). The QPMO plays a vital role by:

- Standardizing and optimizing quality-related governance processes, methodologies, tools, and techniques across projects, promoting efficiency and continuous improvement.

- Developing and maintaining robust governance frameworks that ensure CQM practices are aligned with strategic objectives and facilitate key decisions.

- Fostering talent and capabilities within the organization, including those relevant to quality management.

- Serving as a central hub for knowledge management, facilitating the capture, archiving, and dissemination of lessons learned and best practices related to quality, thereby contributing to organizational learning.

The PMO should consist of Project Management Professionals from diverse disciplines, such as Construction, Engineering, Business, Information Technology, and Risk Management. This multidisciplinary team ensures a common language and integrated understanding when navigating the complexities of organizational Change Management. Implementing an Integrated Construction Quality Management System requires a comprehensive, cyclic, and structured approach to change management, transitioning individuals, groups, and the entire organization from the current state to a desired future state with sustained business benefits. This involves preparing the organization, mobilizing stakeholders, and continuously tailoring the approach to fit the unique organizational context.

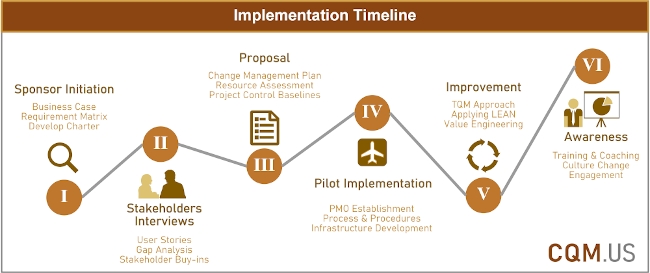

CQM Implementation Timeline

Implementing the comprehensive QualityPMO System requires a structured and phased approach to integrate advanced Quality Management across construction projects. This section outlines the CQM Implementation Timeline, detailing the strategic steps involved in establishing a dedicated Quality Project Management Office (QPMO) and embedding “safety-first, quality-always” practices from project inception through facility handover. The methodology, aligned with industry best practices such as PMI’s project phases and Lean improvement cycles, is designed to systematically address all critical elements from executive sponsorship to continuous improvement. With options for a fast-track (approximately 6 months) or a full transformation (9-12 months), this timeline ensures a tailored yet robust deployment of Digital PMCM, Building Information Modeling (BIM), and AI-driven analytics to achieve measurable improvements and transform the client into a learning organization.

I. Sponsor Initiation:

This initial phase focuses on securing top-level alignment and championship for the QualityPMO System. It begins with interviews and workshops with the executive Sponsor, such as a Vice President of Construction or Chief Engineer, to define strategic goals like reducing the cost of poor quality by 50% or achieving zero significant safety incidents within a specified timeframe. Constraints, including budget limits or existing contracts, are also identified. The strategic leadership (CMBA agent) ensures the program aligns with broader business strategy, culminating in a Program Charter drafted and approved by the Sponsor, formally anchoring the initiative’s purpose to organizational strategy and scope.

II. Stakeholders Interviews:

This stage involves a thorough assessment of the client’s current project and quality management maturity, often guided by PMI’s OPM3 model. This includes structured questionnaires, document reviews, and in-depth interviews with various stakeholders across organizational, portfolio, program, and project levels to understand existing governance, processes, technology, people skills, and culture. The aim is to identify pain points such as siloed data, reactive issue management, and limited accountability, as well as to gather baseline metrics like rework percentages and RFI resolution times. This assessment identifies gaps against industry best practices and provides a Maturity Profile or Scorecard highlighting areas for improvement, and may include a change readiness survey to gauge employee sentiment.

III. The Proposal Stage:

Following assessment, this phase establishes the foundational structure for the quality program. It involves defining decision-making bodies like a Steering Committee and a Working Group, and formally drafting RACI and R2A2 matrices to clarify Roles, Responsibilities, Accountabilities, and Authorities. Key QPMO Leads, including an independent consultant and a client liaison, are appointed to drive methodology and ensure internal buy-in. Concurrently, the core QPMO team with dedicated domain directors (e.g., Field Quality & Safety, Digital Integration) is stood up, receiving initial training and coaching on standards, tools, and Lean Six Sigma basics. A Digital PMCM (Project/Program Management & Construction Management) technology stack is deployed, involving the selection and configuration of systems for PMIS, QMS, BIM/CDE, field data collection, and BI & Reporting, emphasizing integration and “single source of truth” principles.

IV. Pilot Implementation:

This stage involves the launch of the QualityPMO approach on one or more selected pilot projects. The pilot project teams, including contractors, receive intensive training and coaching on new QA/QC processes and the digital tools. The digital tools go live, enabling real-time logging of Non-Conformance Reports (NCRs), RFI tracking, and BIM issue management. A basic Pilot Dashboard is established to capture and visualize early data. Weekly pilot reviews are conducted by the QPMO core team to monitor metrics, gather qualitative feedback, and make immediate adjustments to processes or tool configurations, allowing for on-the-fly refinements based on practical application.

V. Improvement Phase:

Building on pilot successes, this phase focuses on evaluating pilot performance against KPIs and conducting lessons learned meetings to identify what worked and what needs improvement. The QPMO framework, including procedures, training, and tool configurations, is refined and standardized based on this feedback, resulting in an updated QPMO Playbook. The system then expands to additional projects, with a phased rollout and targeted training for new teams. Continuous improvement is embedded through PDCA (Plan-Do-Check-Act) cycles and the formalization of how lessons from one project are incorporated into standards for subsequent ones, potentially establishing a Quality Knowledge Base. This stage also involves deeper cultural interventions, such as introducing a Quality Champion Network, and refining analytics and AI models with richer data from multiple projects.

VI. Awareness Phase:

This ongoing phase is dedicated to driving adoption and fostering a sustainable learning organization culture across the client’s entire enterprise. It involves establishing a Just Culture, where employees are encouraged to report errors and near-misses without fear of unfair blame, supported by leadership endorsement and safe reporting channels. A formal Change Management Plan details frequent communications, highlighting quick wins and reinforcing the importance of quality through executive messages, town halls, and newsletters. Training and coaching are continuous, covering quality management principles, digital tool usage, and essential soft skills like critical thinking and communication. An operating cadence of daily huddles, weekly QPMO meetings, and monthly Steering Committee reviews is established to ensure continuous feedback and adaptation, solidifying the idea that quality management is “part of the DNA of project delivery”.