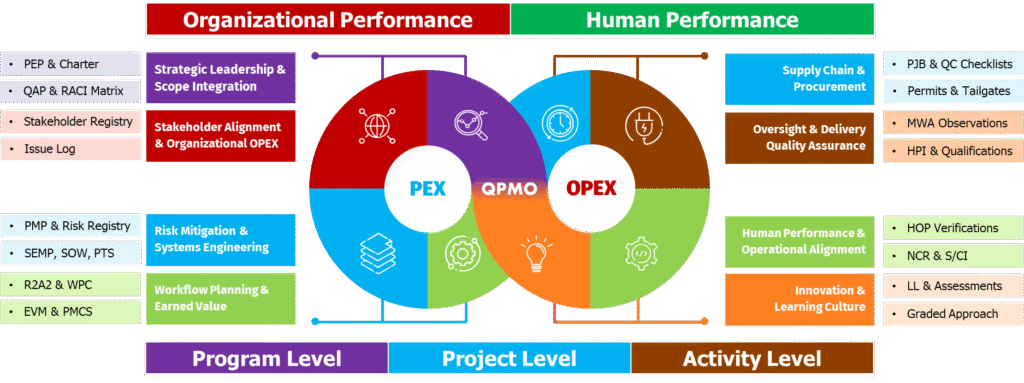

The QPMO methodology is presented as a strategic and integrated framework designed to enhance both Organizational Performance (red) and Human Performance (green) by seamlessly interlocking business/technical governance with field/people practices through an infinite (eight-shaped) continuous improvement cycle from Project Excellence (PEX) in the office to Operational Excellence (OPEX) in the field. This comprehensive approach is applied across three distinct levels: Program (purple) → Project (blue) → Activity (brown), ensuring a consistent and adaptive flow of value from strategy to execution and back into strategic refinement.

🟥 At the Program Level, QPMO establishes Strategic Leadership & Scope Integration. The Project Execution Plan (PEP) and Charter serve as the foundational mandate, defining the program’s purpose and authorizing its formation, thereby providing strategic direction and a clear vision for change. The Quality Assurance Plan (QAP), with its documented procedures and management commitment, along with a RACI Matrix, clearly delineates roles, authority, and accountability for quality throughout the program. A Stakeholder Registry and Issue Log provides structured identification and management of all internal and external stakeholders, fostering effective engagement and communication. The Project Management Plan (PMP), integrating scope, schedule, and cost, along with a Risk Registry, establishes a comprehensive framework for managing program activities and controls. The QPMO philosophy, guided by LEED for sustainability and Total Quality Management (TQM) for continuous improvement, underpins these planning efforts, ensuring strategic alignment and value delivery. For operational execution at this level, Supply Chain & Procurement processes are managed, ensuring proper contract management and quality standards for suppliers. Oversight & Delivery Quality Assurance are paramount, with structured reviews and quality control measurements to build confidence in future outputs. Human Performance & Operational Alignment are enhanced by developing talent and capabilities and ensuring new processes are owned by operational teams. Innovation & Learning Culture are fostered through agile adoption and knowledge management, utilizing tools like BIM and Digital Twins for virtual simulations and constructability reviews.

🟦 Moving to the Project Level, the QPMO emphasizes Risk Mitigation & Systems Engineering to manage complexity and uncertainty. The PEP and Charter continue to guide the project’s direction, aligning it with program objectives. A comprehensive QAP, alongside RACI charts, defines responsibilities and accountability for quality execution. The Stakeholder Registry and Issue Log are actively maintained to address concerns and ensure effective communication. The Project Management Plan (PMP) is integrated with a Risk Registry to proactively identify, analyze, and plan responses for threats and opportunities, aligning with the principle of “Optimize Risk Responses”. Although specific “SEMP” and “PTS” documents are not explicitly detailed, the QPMO framework integrates a “systems view” and leverages concepts from “Systems Engineering Handbook” for robust requirements management, ensuring project components are well-defined and interconnected. For Workflow Planning & Earned Value, the Work Breakdown Structure (WBS) is a foundational tool for defining scope, organizing work, estimating, and scheduling, linking potential risks to specific elements. Earned Value Management (EVM) is consistently applied to integrate scope, schedule, and cost, objectively measuring project performance and forecasting outcomes. The operational side involves Supply Chain & Procurement activities, including working with contracting professionals and vendors, with clear governance for contract changes. Oversight & Delivery Quality Assurance include quality control processes, inspections, and audits to ensure deliverables meet requirements. Human Performance & Operational Alignment are supported by continuous team development, improving competencies, and fostering a climate of trust. Innovation & Learning Culture are propelled by applying continuous improvement cycles like Plan-Do-Check-Act (PDCA) and fostering knowledge sharing.

🟪 At the Activity Level, QPMO focuses on detailed execution and assurance, ensuring Workflow Planning & Earned Value are meticulously managed. Inputs include detailed Work Planning & Control (WPC), explicitly breaking down scope into manageable work packages (WPs) and control accounts (CAs), where scope, budget, schedule, and quality are integrated and baselined. Earned Value Management (EVM) is continuously applied to track progress against this baseline, providing performance metrics at the work package level and enabling early warning of deviations. Quality is embedded proactively, aligning with the principle of “Build Quality into Processes and Deliverables”. On the operational side, Supply Chain & Procurement activities are managed down to the material and equipment level, utilizing tools for efficient physical resource management. Oversight & Delivery Quality Assurance are ensured through QC Checklists, Permits, and implicit safety-related “Tailgates” which are part of establishing clear processes and controls. Human Performance & Operational Alignment are assessed through MWA Observations (implied from “observation, oversight” for quality assurance), emphasis on Human Performance Improvement (HPI) through qualifications and competency development, and verification against HOP Verifications (implied from risk resolution and scope audits as part of ensuring conformity). Innovation & Learning Culture are supported by documenting Lessons Learned and conducting Assessments using a Graded Approach to tailor efforts based on project complexity and risk, ensuring that institutional knowledge is not lost and is used to improve future projects. Specific controls include addressing Nonconformance Reports (NCR) and managing Suspect/Counterfeit Items (S/CI), to ensure compliance with quality standards.

In the big picture, the QPMO acts as the central orchestrator, driving continuous improvement in an eight-shaped cycle. The Organizational side (left stack), with strategy and governance artifacts like the PEP, PMP, and QAP, along with stakeholder and risk registers, provides the inputs that drive Project Excellence (PEX) in planning and collaborative creativity in the office. These artifacts ensure clear direction, resource allocation, and risk management through robust governance frameworks that align with organizational strategy. Concurrently, the Human side (right stack), encompassing efficient supply chains, diligent quality assurance, optimized human performance, and a vibrant learning culture, leverages field practices and people systems to drive Operational Excellence (OPEX) and successful execution in the field. The QPMO synchronizes these efforts across all levels (Program → Project → Activity) by ensuring risks are systematically identified and managed, roles and responsibilities are clearly defined, supply chain and quality assurance are tightly controlled, and continuous learning loops (such as PDCA cycles and lessons learned workshops) are embedded to perpetually improve performance and foster organizational agility and innovation. This iterative interlock ensures that strategic objectives are reliably executed, benefits are realized, and the organization continuously adapts and improves, achieving long-term value and competitive advantage.

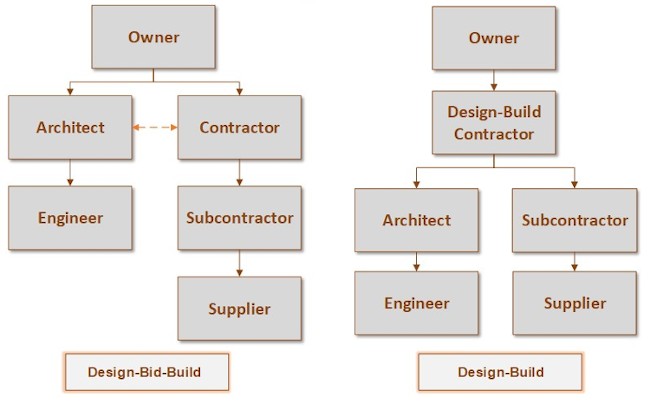

Traditional Construction Project Structure

The Traditional Construction Project Structure, as you’ve described, is characterized by its inherent rigidity, formality, and communication restrictions primarily driven by contractual agreements. In this model, risks and responsibilities for service and quality are often compartmentalized, or “bucketed,” for each entity through separate contracts, with owners frequently engaging multiple independent contractors, who then manage their own subcontractors.

While the introduction of Design-Build (DB) delivery systems aimed to improve the speed of decision-making in the design process and shift risk to the General Contractor, neither this nor the traditional Design-Bid-Build (DBB) model inherently guarantees smooth and integrated quality management assurance for the owner.

A PMI-CP aligned approach to improving this traditional structure emphasizes overcoming these challenges through enhanced integration, communication, risk management, and a continuous improvement mindset across all project levels, from strategy to execution.

Here’s an improved perspective, drawing on PMI-CP principles and the QPMO framework:

Weaknesses of Traditional Construction Project Structures:

- Fragmented and Restrictive Communication:

- In traditional settings, communication is often complex, fragmented, and dynamic, involving many parties with varying contractual arrangements. A simple written statement can lead to multiple interpretations and confusion, directly impacting time, cost, and scope.

- Contract documents, while foundational, can be a source of miscommunication if they lack clarity, leading to unclear scope and objectives.

- Poor communication is a chronic issue that affects time, cost, scope, and can even contribute to high accident rates and disputes. Without effective systems, information sharing and issue resolution are hampered.

- Siloed Risk and Responsibility & Ineffective Change Management:

- Contracts are often “executed in silos,” leading to misunderstandings of terms, flawed structures, and downstream issues and disputes.

- Risk apportionment can be problematic, as the Design-Build model, for instance, “may inhibit the incentive to fairly allocate risk to the party most suited to manage it,” leading to conflict and claims.

- In DBB, if issues arise, designers and contractors may blame each other, causing litigation and delays.

- Poor project planning and scope definition often result in frequent changes, project delays, budget overruns, and ultimately, project failure.

- Scope creep is common when additional features are added without accounting for impacts on time, costs, and resources, detracting from project objectives and quality. This is exacerbated by inconsistent or poor change management processes and a lack of communication among stakeholders.

- Lack of Integrated Quality Management & Assurance:

- Traditional QA programs can sometimes lack sufficient detail and controls.

- Quality is often an afterthought, relying on inspection rather than being “built into design prior to starting work”.

- Diverse roles (Business Manager, Developer, Regulator, Legal Counsel, Architect, LEED Expert, General Contractor, Subcontractor, Inspector, Supplier, Project Manager, BIM Modeler, Scheduler, Quality Manager, Engineer, Technician, Laborer) each have their own perspective on project phases based on their accountability and responsibilities, leading to potential misalignments in quality expectations and execution [user prompt].

PMI-CP Aligned Improvements for Enhanced Organizational and Human Performance:

The QPMO framework, aligned with PMI-CP principles, addresses these traditional shortcomings by interlocking business/technical governance with field/people practices in an infinite (eight-shaped) continuous improvement cycle from Project Excellence (PEX) to Operational Excellence (OPEX), across the Program, Project, and Activity levels.

🟥 Program Level – Strategic Leadership & Scope Integration:

- Robust Governance Frameworks: Establish a Project Risk Governance Board with a single point of accountability and clearly defined roles and responsibilities from the outset. This board streamlines communication and decision-making for risks and ensures timely information flow through formal monitoring and reporting schedules.

- Strategic Alignment: The Project Execution Plan (PEP) and Charter provide a clear mandate and vision, aligning all program components with organizational strategy [user prompt]. OPM governance integrates portfolio, program, and project management practices, ensuring strategic alignment of initiatives to objectives.

- Integrated Risk Management: Develop a Quality-Linked Risk Baseline by tying identified risks to measurable quality and performance benchmarks derived from business objectives. This incorporates risk appetite and thresholds early on.

- Continuous Improvement Philosophy: Embed principles like “Build Quality into Processes and Deliverables” and “Optimize Risk Responses”. The QPMO, guided by LEED for sustainability and Total Quality Management (TQM) for continuous improvement, underpins these efforts.

🟦 Project Level – Risk Mitigation & Systems Engineering:

- Enhanced Communication and Collaboration:

- Implement Interface Management (IM) to strategically manage communication, relationships, and deliverables among interdependent stakeholders. This involves using tools like the Project Interface Risk Impact (PIRI) matrix and the Interface Complexity Assessment Tool (ICAT) to assess and manage cross-disciplinary risks, formalizing communication, and clarifying deliverables.

- Foster Commitment-based Management (CbM), where requests and commitments are clear, explicit, and mutually negotiated, ensuring all parties understand and agree to deliverables and associated risks. This removes complexity and encourages people to agree only when clear about outcomes.

- Utilize Project Management Information Systems (PMIS) for quick, accurate information sharing, issue resolution, and timely decision support. PMIS also facilitates enhanced project monitoring and documentation.

- Proactive Planning & Scope Definition:

- Emphasize Front-End Planning (FEP) with detailed scope definition to reduce changes, delays, and budget overruns.

- The Work Breakdown Structure (WBS) is a foundational tool for defining scope, organizing work, estimating, scheduling, and linking risks. A quality WBS is crucial for project success.

- Value Engineering (VE) analysis should be integrated to optimize value, safeguard quality, and enhance safety, focusing on essential functions to reduce rework and improve profitability.

- Adaptive Change Management:

- A robust and streamlined change order management process is essential for assessing modifications against project objectives, performance outcomes, and risk exposure. This process ensures only approved changes are implemented and secondary/residual risks are identified.

- Employ a “systems view” where changes are continuously monitored and plans reassessed, allowing for adaptive responses to emerging issues rather than rigid adherence to initial plans.

🟪 Activity Level – Workflow Planning & Earned Value (and Execution & Assurance):

- Integrated Digital Technologies:

- Building Information Modeling (BIM) and Digital Twins create virtual models for constructability reviews and virtual risk simulations, identifying and resolving conflicts before physical construction. BIM enables early input and refinement of scope and evaluation of change impacts collaboratively.

- IoT and field applications integrated with PMIS analytics provide real-time information and predictive risk alerts, enabling early detection of deviations and corrective actions.

- Performance Measurement and Control:

- Earned Value Management (EVM) integrates scope, schedule, and cost to objectively measure performance, track work progress against baselines, and forecast project outcomes. It provides insights into quality and risk impacts.

- Control Accounts (CAs) and Work Packages (WPs), derived from the WBS, serve as management control points where scope, budget, schedule, and quality are integrated and baselined.

- Risk Accountability Scorecards track team performance in risk management, integrating with EVM to assess impacts on schedule and budget.

- Continuous Learning and Feedback:

- Implement real-time communication channels and structured feedback loops between site teams and project leadership, utilizing PMIS for transparent information distribution.

- Conduct weekly root cause analysis (e.g., using PDCA cycles) for risk occurrences and materialized issues, documenting them in the risk register and lessons learned knowledge vault for future planning and prevention.

- Formal Risk Resolution Summits during closeout verify resolution of all identified risks or their transfer to operational teams, releasing contingency reserves.

- Knowledge Vault Archiving ensures all risk and quality-related data, documentation, and analyses are stored in a centralized, retrievable format for benchmarking and continuous improvement.

By embracing these PMI-CP aligned practices within the QPMO framework, the construction industry can transform from rigid, siloed operations to an agile, collaborative, and continuously improving ecosystem. This not only enhances Organizational Performance through robust governance, integrated change control, and strategic alignment, but also significantly boosts Human Performance by fostering a culture of clear communication, shared responsibility, continuous learning, and empowered decision-making, ultimately delivering projects with greater predictability, quality, and value.

The Traditional Construction Project Structure, as previously discussed, often struggles with smooth and integrated quality management assurance for the owner due to its inherent rigidity and formal nature. Communication is frequently fragmented and dynamic, hindered by contractual arrangements that can lead to misinterpretations and confusion, ultimately impacting project timelines, costs, and scope. Responsibilities and risks are typically “bucketed” for each entity, with owners contracting separately with designers and contractors, who then manage their own subcontractors [user prompt]. This siloed approach makes it difficult to achieve a unified vision of quality, as each role—from Business Manager to Laborer—operates with its own perspective based on specific accountability and responsibilities.

These traditional limitations, coupled with the increasing complexity arising from a variety of systems, designs, specifications, brands, methods, and techniques, made it increasingly challenging to control all project requirements and stakeholder expectations. This environment often led to rising costs associated with poor quality, increased litigations, and a culture of mistrust and blame, where contractual boundaries exacerbated disputes rather than fostering collaboration. The cost of quality encompasses not just the expense of preventing nonconformance, but also the significant costs of appraisal and, crucially, the substantial financial and reputational damage from failures, especially when issues are discovered late in the project or during the operational phase.

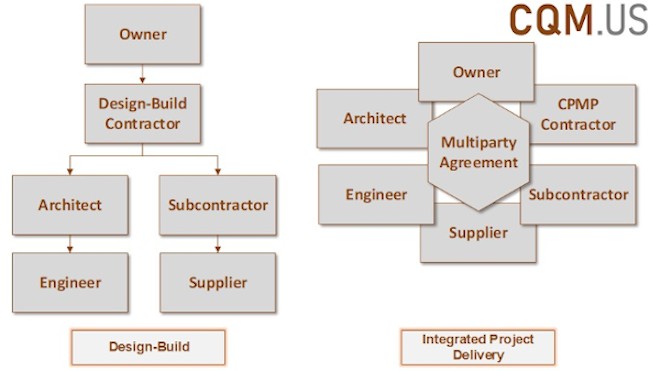

Integrated Project Delivery (IPD): A Collaborative Response

In response to these systemic challenges, Integrated Project Delivery (IPD) emerged as a crucial approach emphasizing partnerships and collaboration among all key stakeholders—including owners, designers, and contractors—to increase value by reducing waste and maximizing efficiency throughout all phases of design and construction. IPD, aligned with PMI-CP principles, champions a systems view of value delivery, recognizing that projects do not operate in isolation but are part of an integrated system designed to achieve strategic organizational outcomes.

Key improvements facilitated by IPD under a PMI-CP aligned framework include:

- Holistic Quality Management and Assurance: IPD moves beyond traditional inspection-based quality control to proactively build quality into processes and deliverables from the design phase onwards. This involves clearly defining quality requirements and standards, with compliance demonstrated across all project components, and focusing on meeting customer expectations and delivering value to beneficiaries. By fostering early collaboration (e.g., through Value Engineering (VE) analysis), IPD optimizes value, safeguards quality, and enhances safety, thereby reducing the likelihood of costly rework and disputes.

- Integrated Risk and Contract Management: A central tenet of IPD is to spread liability, responsibility, risk, and rewards among all stakeholders, fostering mutual goals and incentives embedded within contracts. This contrasts with models where risk allocation may be unbalanced, leading to conflict and claims. IPD often utilizes one overarching contract, which eliminates the risk of misalignment or misinterpretation of documents common in multi-contract environments, significantly reducing the likelihood of litigation. The emphasis is on using clear, concise, and unambiguous language in contracts to prevent differing interpretations and define scope clearly during front-end planning.

- Enhanced Communication and Collaboration: IPD actively fosters a collaborative project team environment where information and knowledge are freely exchanged. This aims to overcome fragmented communication by establishing dedicated channels and structured feedback loops, especially important in complex, multidisciplinary environments. Commitment-based Management (CbM) is integral to IPD, ensuring that requests and commitments are clear, explicit, and mutually negotiated, promoting shared understanding and accountability for deliverables and risks.

- Waste Reduction and Efficiency: By bringing together key skills early and promoting continuous improvement, IPD (often aligned with Lean methods) seeks to minimize handoffs, errors, and waste across all project phases. Digital technologies like Building Information Modeling (BIM) and Digital Twins are leveraged for virtual risk simulations and constructability reviews, allowing early identification and resolution of conflicts and design issues before physical construction, thus preventing costly rework.

- Navigating Complexity and Adaptability: IPD acknowledges that construction projects operate in complex and uncertain environments, where complexity can arise from human behavior, system interdependencies, and ambiguity. Instead of rigid adherence to initial plans, IPD encourages an adaptive and resilient approach, using iterative processes and continuous feedback to respond to emerging changes. Digitalization, with its integrated use of data and linking of physical and virtual objects, opens new opportunities for planning and organizing processes in complex projects.

The Evolving Nature of IPD Definitions

It is accurate that no single, universally prescriptive IPD “system” is available, and organizations like ASCE, AIA, CMAA, LCI, and AGC have developed their own definitions and frameworks [user prompt]. This reflects the reality that governance and project management methodologies must be tailored to fit the specific organizational culture, project types, complexity, and strategic objectives. Different industry perspectives—from lawyers to engineers and architects to contractors—contribute to this diverse understanding, as each discipline has its own language, tools, and practices that need to be aligned within a collaborative framework.

Rather than a “one-size-fits-all” approach, PMI-CP emphasizes tailoring as a deliberate adaptation of the project management approach, governance, and processes to suit the given environment. This involves selecting and blending various elements (e.g., adaptive, predictive, or hybrid life cycles) to maximize value, manage constraints, and improve performance using “just enough” processes, methods, and artifacts. This adaptive approach is crucial for managing the inherent ambiguity and complexity of built environment projects, ensuring that while the core principles of collaboration, shared risk, and integrated value delivery remain consistent, their implementation can be flexible enough to achieve successful outcomes.

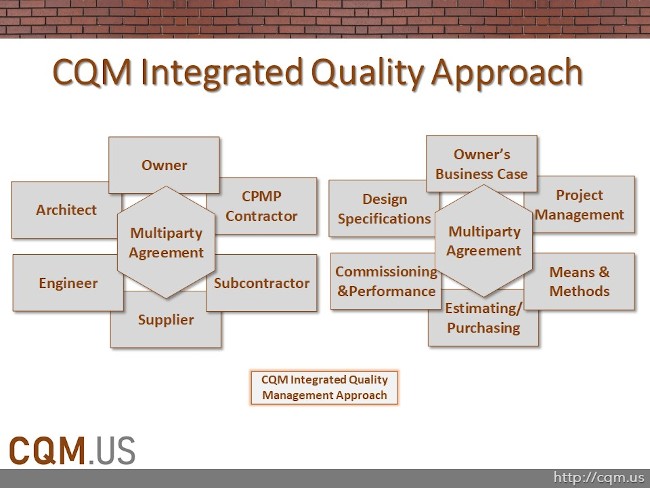

CQM Project Structure

The CQM.US framework strongly advocates for an Integrated Project Delivery (IPD) approach to construction projects, aiming to integrate Quality Management and cultivate a partnership mindset among all team members. This collaborative model is essential for creating a common perspective on quality and ensuring that project outcomes account for Sustainability, encompassing Profit, People, and the Planet.

Integrated Project Delivery and Quality Integration

IPD is a crucial delivery method in built environment projects that emphasizes teamwork and collaboration. Its primary aim is to spread liability, responsibility, risk, and rewards among all stakeholders, fostering mutual goals and incentives embedded within contracts. This is particularly important for quality management, as it moves beyond traditional inspection-based quality control to proactively build quality into processes and deliverables from the design phase onwards.

This partnership mindset is further supported by:

- Commitment-based Management (CbM): CbM offers a systematic methodology for driving action in projects by ensuring that requests and commitments are clear, explicit, and mutually negotiated. This fosters trust and flexibility in work delivery, promoting early communication and team adaptability.

- Collaborative Project Team Environment: Creating such an environment involves establishing team agreements, structures, and processes that support a culture of synergistic interactions. This allows for the free exchange of information and knowledge, increasing shared learning and individual development while delivering desired outcomes.

- “Team of Teams” Principle: This principle characterizes an integrated team structure that creates a network of relationships, enhancing adaptability and resiliency in the face of complexity and uncertainty.

Sustainability: People, Planet, and Prosperity

The approach to sustainability within the CQM framework aligns with the GPM P5 Standard for Sustainability in Project Management. This standard integrates sustainability into project management by considering five elements: Process, Product, People, Planet, and Prosperity (the latter encompassing Time, Cost, Scope, and Quality). Sustainable project managers are expected to:

- Embrace Ethical Leadership: Leading with purpose, they establish compelling visions and prioritize societal and environmental well-being, demonstrating integrity and honesty.

- Integrate Sustainability Factors: This involves incorporating sustainability into all project activities, identifying ways to mitigate negative impacts, and tracking progress towards sustainability goals using metrics and regular assessments.

- Value Chain Extension: The project’s value chain, including all activities, processes, and functions, should be managed sustainably, extending recommended practices to suppliers, partners, and other stakeholders contributing to the project.

Common Perspective and Multi-layered Quality System

Achieving a common perspective across diverse project teams and stakeholders in the complex built environment requires effective communication strategies tailored to specific audiences and project needs. IPD and CbM specifically address the fragmentation and potential for misinterpretation inherent in traditional construction projects.

The recommended CQM Project Structure employs a Multi-layered System of Quality Control (QC) and Quality Assurance (QA) Framework [user prompt]. This framework is designed to provide robust quality management by:

- Formalizing QA Programs: Organizations should decide whether to use an existing site-wide QA program, the contractor’s corporate QA program, or develop a project-specific QA program. For large or complex projects, a standalone, project-specific QA program, incorporating nationally or internationally recognized consensus standards, may be necessary.

- Graded Approach to QA: The level of QA required should vary with the project’s complexity and risks, ensuring sufficient detail and resources to meet project objectives without over- or under-applying controls.

- Building Quality into Design: Emphasis is placed on building quality into the design phase prior to starting work, rather than solely relying on inspection to find and fix issues later. This proactive approach reduces the high cost of changes associated with fixing quality issues discovered late in the life cycle.

- PMO Support: A Project Management Office (PMO) plays a vital role in standardizing and optimizing quality-related governance processes, methodologies, tools, and techniques, promoting efficiency and continuous improvement.

Role of the Construction Project Management Professional and Shared Responsibility

To effectively meet the owner’s business case requirements, engaging a Construction Project Management Professional (PMI-CP) is highly recommended. PMI-CP certified individuals possess specialized techniques customized for the built environment field. The project manager’s role is critical in leading the project team to meet objectives and stakeholder expectations, balancing competing constraints such as scope, quality, schedule, and budget. They must understand strategic objectives and ensure the alignment of project objectives with portfolio, program, and business area goals, contributing to strategy execution.

The CQM framework advocates for sharing the Quality Responsibility across all project entities. In contrast to traditional projects where quality management might be the responsibility of specific team members, adaptive approaches often involve all team members in quality control activities throughout the project life cycle. This collaborative approach, coupled with strong leadership, cultivates a climate of trust and consistency, enabling effective delegation and cooperation.

Tailoring and CQM Phases

The CQM Methodology is designed to be applicable to all different types of Project Structures [user prompt] because the multi-layered system of QA/QC framework is based on defined CQM Phases. Project management methodologies, including those for quality, must be tailored to fit the specific organizational culture, project types, complexity, and strategic objectives. This tailoring ensures that the approach, governance, and processes are suitable for the given environment and work at hand, maximizing value and managing constraints.

The CQM activities are integrated across the entire project life cycle, spanning:

- Project Definition & Design Planning

- Construction & Installation Execution

- Facility Commissioning and O&M Handover

This integration recognizes the iterative and dynamic nature of quality management, where plans and activities are continuously revisited and refined based on new information and feedback from each phase. Formal stage gate reviews and key milestones are incorporated at critical junctures to assess the current risk and quality profile, confirm readiness, and identify new concerns. The foundational tool for this structure is the Work Breakdown Structure (WBS), which provides a hierarchical decomposition of the total project scope and serves as a baseline for organizing work, estimating, scheduling, and linking risks and quality requirements.

The Owner’s Business Case Requirement will be best met if a Construction Project Management Professional is onboard for Project Management and everyone is sharing the Quality Responsibility in a Multi-layered System of Quality Control and Quality Assurance Framework.

All that said, the CQM Methodology will be applicable to all different types of Project Structures since the Multi-layered System of QA/QC Framework is based on defined CQM Phases that will be covered next!