Construction Quality Management is very closely related to Construction Safety Management.

Many quality negligences will eventually lead to safety hazards because requirements were not performed as expected. That is the definition of quality: Quality is to achieve the ‘right’ expectation!

Defining the “right” expectations is the key when it comes to creating specifications and drawings for construction projects. Validating that the requirements of the specification were performed as directed by the Architect of Record and Engineering compliance to regulations and expectations is Quality Assurance.

CQM Safety News

ENR.com published this news on its website and the September 13/20, 2021 magazine edition:

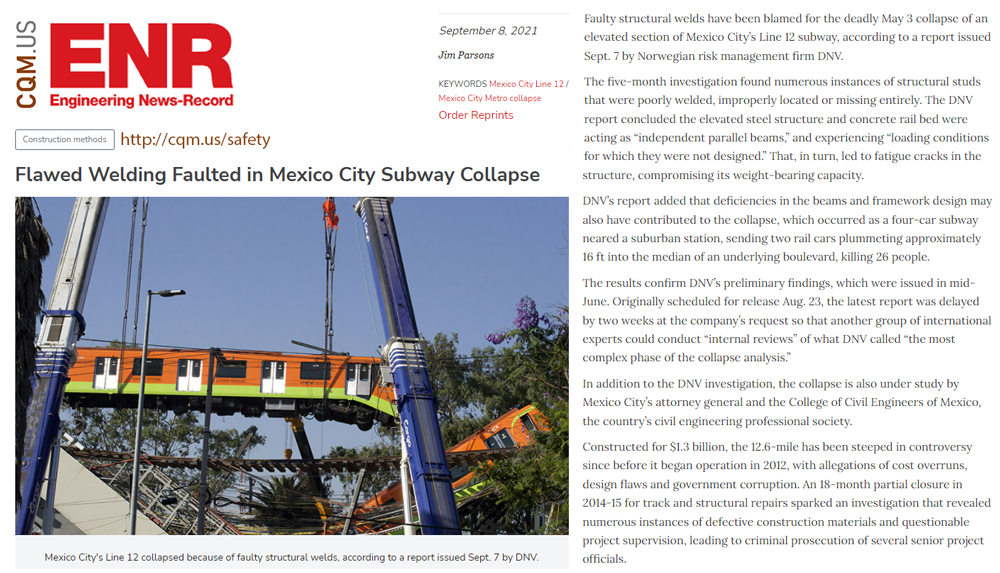

Fatal Accident: Faulty Welds Blamed in Deadly Mexico City Subway Collapse

Faulty structural welds have been blamed for the deadly May 3 collapse of an elevated section of Mexico City’s Line 12 subway, according to a report issued Sept. 7 by Norwegian risk management firm DNV.

The five-month investigation found numerous instances of structural studs that were poorly welded, improperly located or missing entirely. The DNV report concluded the elevated steel structure and concrete rail bed were acting as “independent parallel beams,” and experiencing “loading conditions for which they were not designed.” That, in turn, led to fatigue cracks in the structure, compromising its weight-bearing capacity.

It is very difficult to read news such as this when you know it could have been avoided. Let’s collaborate as a CQM Community to share lessons learned and best practices and improve our profession. Here are the basic steps in creating a Quality Culture that integrates and embeds excellence into all aspects of an organization for construction projects.

- Big Picture: Integration for Construction Quality Management

- Document Review: Expectations & Requirements

- Strategic Alignment: Core Values & Objective Review

- Quality Culture: Awareness and Engagement

- Benchmarking: Collaboration for sharing Best Practices

- Organizational Restructuring: RACI and Roles Responsibilities

- Applying LEAN: Process Value Streaming for better efficiency

- Digital Transformation: Use of Innovation for Automation for better productivity

- Assessment & Training: Collecting Lessons Learned for Lessons Applied

- Celebration and Recognition: Award and promote excellence

Above recommendations are best applied in a Quality PMO setting where governance and coordination are made in a structured and organized framework. To learn more visit http://qpmo.us

CQM.US Community

These best practices shared here are presented by our CQM Experts and more information can be found in our YouTube Channel at https://cqm.us/tv

If you wish to add or modify the above post, please join our CQM Community and we will add you to our CQM Experts with contribution to the website’s content.