CQM Methodology encourages continuous improvement, research, and development to find Best Practices available to the Construction Industry and advocates to promote collaborative knowledge sharing. With the advancement in Data Information Technology, new knowledge and innovative solutions are created, published, and distributed in minutes. Through the CQM Community recommendations, these new innovative solutions are tested and practiced to fit properly within the CQM Framework. Therefore, there are unlimited methods and techniques practices, but the Construction Quality Management Profession can always count on the recommended Best Practices in CQM Methodology.

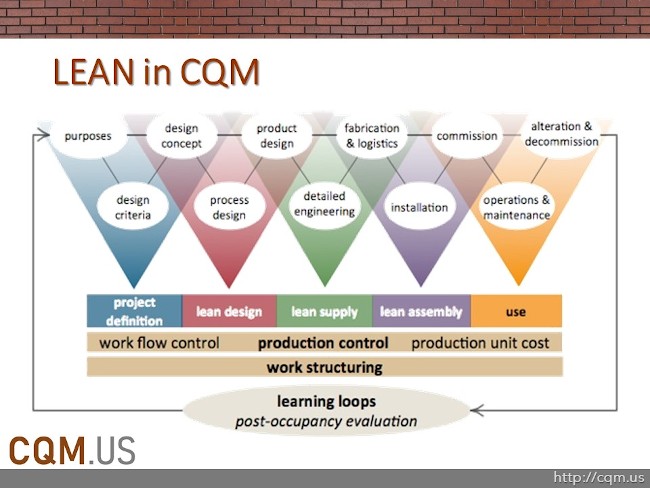

Lean Construction in CQM

Considering the unlimited number of tools and techniques available to fit within the CQM Framework, CQM Methodology recommends a Lean approach to eliminate waste and improve efficiency in the CQM Implementation. Although Lean Principles were first introduced by Toyota in 1990s for manufacturing, Lean Construction Institute has been one of the main references and advocates of Lean application for the Construction Industry.

CQM Methodology encourages the implementation of Lean Construction Principles as follows:

- Identify Value from the Customer’s Point of View

- Define the Value Stream

- Eliminate Waste

- Flow of Work Processes

- Pull Planning and Scheduling

- Continuous Improvement

As discussed before, most of these principles are overlapped with TQM in CQM and PMI in CQM such as Identify Value, Define Value Stream, and Continous Improvement, therefore with a LEAN mindset, CQM focuses on “Eliminate Waste” and “Deliver Fast through Flow of Work Processes” and “Pull Planning for scheduling” aspects of Lean in CQM.

In addition, Lean in Construction has introduced some practical and useful tools and techniques such as Last Planner for scheduling that is highly recommended by the CQM Methodology as a best practice.

The Lean Principles come especially handy for the Integrated Project Delivery method recommended by CQM to avoid Over-processing, excess motion, over-production, non-utilized talent, excess transport, delays, correction and unnecessary inventory of design and construction-related activities!

As an example, SSOE has a great methodology and 4BTOpenJOC has a great tool that could be used to promote and apply Lean Construction principles for IPD with the help of BIM.

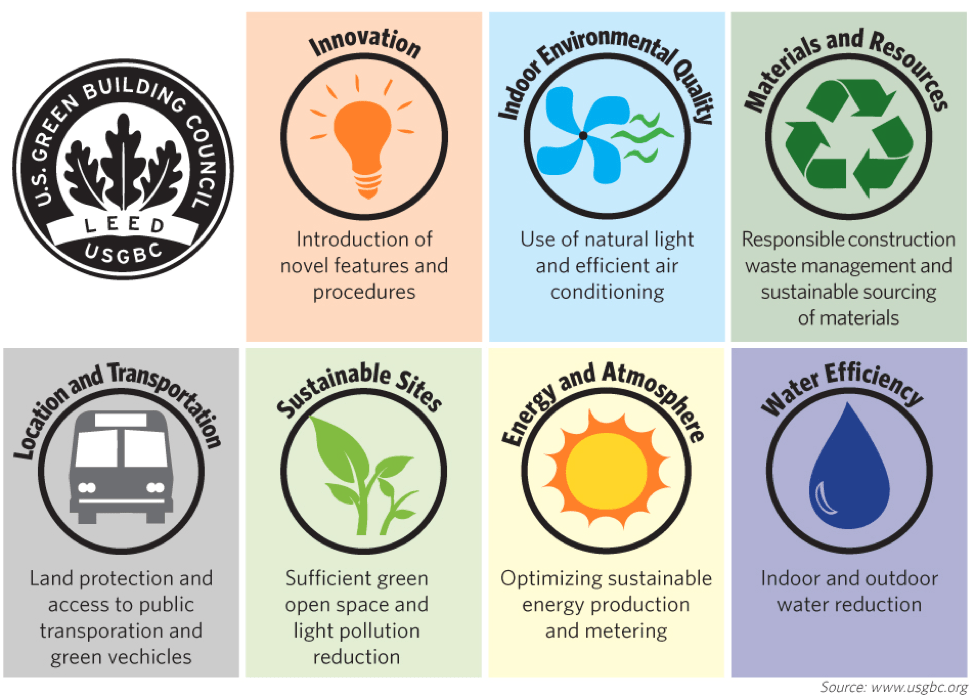

LEED in CQM

Another best practice that is highly recommended and used in the CQM Methodology is the LEED Philosophy for sustainability and the 3Ps: Profit, People, and Planet

Although Leadership in Energy and Environmental Design principles are applied for Green Buildings, CQM Methodology encourages the Quality Manager’s involvement in an early stage of the project to assist and manage LEED aspects of the Quality Management Program for Construction Projects.

LEED principles ensure design and construction consideration for a better quality product, however, a CQM Professional understands that without a proper Quality Management Program, these principles might be compromised and in many cases neglected since the majority of the Construction Management Team are unfamiliar with the importance of the LEED Philosophy.

Furthermore, CQM IPD encourages a sustainability mindset for organizational sustainability even before the conception to establish the business case and start the pre-construction phase as an integrated quality excellence mindset in all aspects of the construction project.

Other Best Practices

The CQM Methodology is a robust system where new Best Practices and Principles are fit into the CQM Methodology as the CQM Community makes recommendations for better CQM Implementation.

There will be new Best Practices in CQM introduced in this section in the future with an explanation on how to practically apply these practices for a more practical quality management methodology!