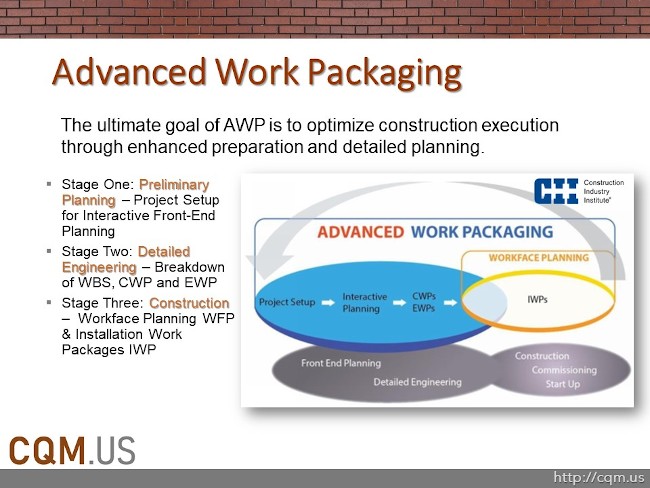

CQM Methodology encourages the use of Construction Industry Institute’s Advanced Work Packaging Best Practice as a process in creating Work Break Down Structures as well as its Installation Work Packages as a tool to for Construction Quality Management.

Many in the Construction Project Management profession are aware of the Project Management Institute’s Practice Standard for Work Breakdown Structures needed to create control accounts for Cost and Scheduling Controls. Although CQM Framework is based on PMBoK Framework, however when it comes to an Integrated Construction Quality Management, the CQM Methodology recommends CII’s Advanced Work Packaging (AWP) best practice.

The AWP was developed through a collaboration between the Construction Owners Association of Alberta (COAA) and CII to be recognized as a CII Best Practice in September 2015. CII defines AWP as follows:

Advanced Work Packaging is the overall process flow of all the detailed work packages (construction, engineering, and installation work packages). AWP is a planned, executable process that encompasses the work on an EPC project, beginning with initial planning and continuing through detailed design and construction execution. AWP provides the framework for productive and progressive construction, and presmnes the existence of a construction execution plan.

See Research Team 272, “Advanced Work Packaging: Design Workface Execution,” implementation Resource 272-2, Version 3.1, Vol. 1 (October 2013) 7, pp. 7.

Installation Work Packages (IWP)

The AWP process strategically breaks down the construction scope into distinct and manageable packages. The AWP process commences in early engineering and cascades through the project life cycle to provide the construction team the ultimate and eventual deliverable, the Installation Work Packages (IWP). Each IWP is designed to identify and provide a single discipline crew (e.g., civil, structural, piping, mechanical, electrical, and instrumentation) all the constraint-free requirements necessary to safely and efficiently commence and complete the defined work scope. (source: Long International)

However, according to the CII definition for IWP there will be too many IWP to be handled by the team for a large project. Therefore, CQM has adapted and customized the Best Practice by applying the USACE CQM-C methodology for the Definable Feature of Work (DFoW) to provide IWP packages in fewer more manageable categories.

Definable Features of Work Definition

According to the USACE Best Practice, Definable Features of Work in a project are each individual task of a project that must be sufficiently broken down for the QC process. To properly manage quality on a project, each activity must be broken down into very specific activities or DFoW.

When developing a DFoW List the following must be considered:

- Every task that requires a separate Quality Preparatory Meeting and Inspection coordination per Industry Standards or the Contract

- Use the contract specifications by sections to identify separable DFoW.

- Think about work crews and the coordination required between trades. If a new crew is required to do the work, there is a new DFoW.