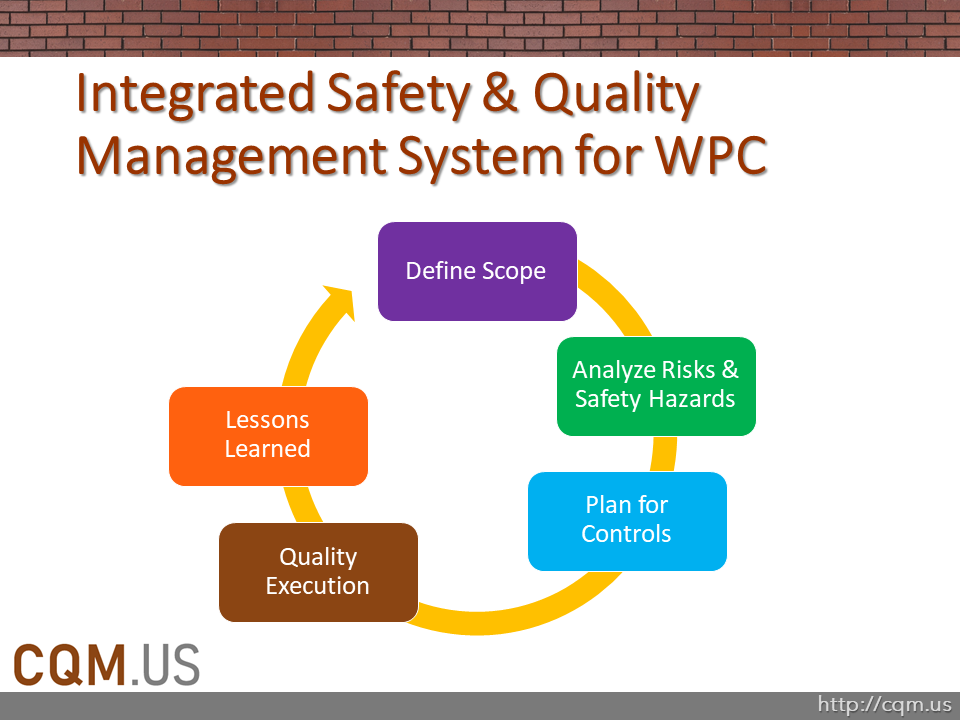

Work Planning and Control as part of CQM

Work planning and control (WPC) is the use of formal, documented processes for identifying and mitigating risks when planning, authorizing, releasing, and performing work. The purpose of WPC is to ensure adequate protection of workers, the public, and the environment, which would otherwise be put at risk by inconsistent and inadequate planning, authorization, and control.

WPC covers all activity-level work performed in or on facilities, including technical and administrative activities, construction, experiments, operations, maintenance, and service. The program also covers the stop-work process as part of performing work within controls.

WPC for Construction Quality Assurance

WPC covers QualityPMO core functions for an integrated safety and quality management system for construction projects by:

- Define the scope of work

- Identify Risks & safety hazards

- Plan for Controls

- Quality Execution

- Authorize & Release after Quality Preparatory Meeting

- Continuously Monitor and Supervise Work

- Work with End-in-Mind, record documents for verification

- Collect Lessons Learned for continuous improvement

A visit to the job site is warranted, as well as a discussion with the key stakeholders to review area hazard analysis (AHA). The results are documented in a WPC form, that authorizes and releases the work activity for quality execution. Authorization means that the person who authorizes the work

- A competent person with sufficient knowledge of the hazards has a plan and authorization for such work

- Has determined the work falls within their area of expertise and responsibility

- Is satisfied with the content of the work plan

- Has been determined that the persons assigned to perform work are qualified

- Has discussed hazards and controls with those people

The person who authorizes work is accountable for its performance. Work is typically authorized by the supervisor and line manager of the person performing the work.

PM 4 CQA

The June 2023 event will focus on how Project Managers are a critical element in planning ahead for an effective WPC at the activity level.

We have invited Robert Gittens from BIMSync’d to continue the discussion on Scheduling and better methods and techniques using BIM 4D to engage all stakeholders and visualize the result using innovative technologies.

BIM4D as a Single Source of Truth for WPC

Work Planning & Control

- Planning for Requirements

- Early Engagement of Stakeholders

- Ensuring proper use of resources

Integrating Safety & Quality Management

- Scheduling Safety Supervision

- Scheduling Quality Assurance Experts

- Controlling Procurement of Quality Material & workmanship

Schedule and BIM 4D

- Communication & Collaboration Tool

- Visualization & Conflict Resolutions

- Single source of truth to extract updated project information

Please invite other guests and experts that could contribute to the discussion as we share best practices and learn from each other.

If you are not a member of either chapter, it’s okay! The event is free and open to all managers, students, and emerging professionals!

All events are found at https://cqm.us/events

WPC for Construction Quality Assurance

During our March 2023 quarterly event, Sara did a great job summarizing our goal as a community of practice regarding Work Planning and Control. We invited Chris Carson, the PMI Scheduling Guru, to discuss the importance of Schedule Quality for ensuring proper communication and planning for work activities.

Dr. Emari presented the Department of Energy’s definition and expectation of a Construction Quality Assurance program to ensure proper WPC to integrate Safety and Quality for all projects.

The recordings are on our YouTube channel at https://cqm.us/tv

WPC 4 CQA

Dr. Harri Emari, the Construction Quality Assurance Manager for SLAC National Laboratory at Stanford, emphasized the importance of learning together, actively listening, and integrating safety and quality in a “Safety First Quality Always” mindset.

Dr. Emari explained that work plan control is a standardized process that helps ensure safety and quality in construction projects, particularly those involving federal government entities, which have mandated regulations for public safety. Work plan control involves understanding the scope of work, identifying qualified workers, evaluating and controlling hazards, communicating controls to workers, authorizing and coordinating work, and releasing the work to be performed.

During the presentation, Dr. Emari highlighted that work plan control is not just about safety but is also a quality assurance requirement. Quality assurance involves all the actions necessary to provide confidence that the quality of a product or service is achieved. The Department of Energy’s (DOE) quality assurance requirements are mandated through federal regulations and flow down to contractors working on DOE projects. Dr. Emari divided the 10 criteria of DOE order into three levels: management, assessment, and performance. While quality assurance focuses on the management and assessment sides, it is integrated into all aspects of design, engineering, and execution on construction sites.

The integrated safety and quality management policy is a multi-layered system at SLAC that involves project management practices, engineering policies, and QA programs to ensure safety and quality in all aspects of the company’s operations. This system includes work planning and control (WPC), which happens at multiple levels, from master planning to daily hurdles, and involves continuous improvement through feedback and lessons learned. All Quality Management Systems must use technical standards, handbooks, specifications, and manuals to translate these policies into practical requirements for their staff and subcontractors.

The CQM methodology emphasizes commitment, core values, and alignment with quality assurance programs as it engages qualified people for continuous involvement and monitoring through business intelligence for feedback and improvement. Dr. Emari discussed the importance of quality assurance in project management and how new technology, specifically BIM, can improve it. He emphasized the importance of managing documents, controlling work processes, and having competent people work on projects to ensure quality. Dr. Emari discussed how a Quality Culture of collaboration and proactive problem-solving is crucial for maintaining quality assurance through a QPMO.

CQM CoP invites all professionals and students to connect on LinkedIn to continue the discussion and provide feedback. We will further expand on this topic and introduce methods and tools such as BIM 4D in upcoming events. As always, CQM promotes continuous improvement and collaboration to achieve high-quality results in construction project management.

Quality Schedule 4 WPC Communication

The importance of quality control and standards in project management cannot be overstated, according to Chris Carson, the PMI Scheduling Guru from Arcadis for over 45 years. Carson’s agenda for the day is to discuss quality control and standards, their relationship to workflows, and the use of standard documents. He believes that high-quality standards require a commitment to industry best practices, leadership in developing these practices, and their adoption into company procedures with training and review processes. This approach builds quality into the work product instead of inspecting it after the fact.

Standardization is essential for quality control, and Carson has found that standardizing processes and procedures, even with modifications for clients, is the best approach. His company offers 175 unique deliverables for project control services, and they aim to standardize and describe each deliverable as a unique product with tasks broken down for review. This leads to an educational component where people better understand what needs to happen, and the quality of the end product is improved.

Carson emphasizes the importance of industry-standard supporting documents, requirements planning, and the use of the schedule as the main communication tool. Project controls are critical to managing communication and ensuring safety and quality management. Standardizing deliverables, procedures, and workflows leads to consistent, high-quality output, making a significant difference in the end product.

The speaker stresses the need for a single source of truth and to document the schedule and estimate. Productivity data is crucial for developing estimates and schedules for a project. It is crucial to engage stakeholders early in the process to ensure their buy-in and understand their expectations. Safety considerations, design integration, and allocating sufficient time for quality control, reviews, and inspections are all critical elements in the project management process.

In conclusion, Chris Carson’s extensive experience in the industry highlights the importance of standard processes and procedures in project management, particularly in construction projects. Using capacity factoring, training, and certification, as well as integrating change management with scheduling and cost, can lead to successful project outcomes. Adopting BIM 4D can also aid in improving project planning and communication. By emphasizing careful planning, stakeholder engagement, safety considerations, and documentation, project managers can ensure the success of their projects and the satisfaction of their clients.

Subscribe to CQM channel

Subscribe to CQM channel