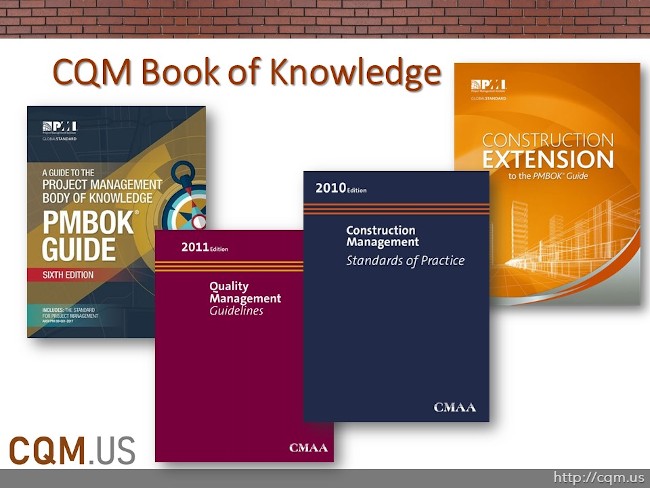

For a comprehensive understanding and effective implementation of the Integrated Quality Management (CQM) Methodology, it is essential to establish a CQM Book of Knowledge. This repository will gather the specialized terminology, processes, inputs, and outputs necessary for communicating quality management tasks seamlessly with all other project management activities. Its purpose is to serve as a structured reference and training resource.

The CQM Book of Knowledge aligns with and extends PMI’s foundational standards, such as A Guide to the Project Management Body of Knowledge (PMBOK® Guide), The Standard for Program Management, and The Standard for Portfolio Management, as well as a suite of specialized practice guides. These include:

- Practice Standard for Project Configuration Management: Essential for maintaining integrity of project items, ensuring only approved changes, and providing traceability and version control for documents and deliverables.

- Requirements Management Practice Guide: Crucial for defining and managing high-level business requirements that align with strategic objectives and stakeholder expectations.

- The Standard for Earned Value Management: Provides methodology for integrating scope, schedule, and resources, objectively measuring performance, and forecasting project outcomes, which can include quality and risk impacts.

- Managing Change in Organizations Practice Guide: Outlines essential change management capabilities embedded throughout portfolio, program, and project management to ensure successful strategic shifts.

- Navigating Complexity Practice Guide: Addresses the skills and capabilities needed to successfully mitigate complexity in projects and programs, which is highly relevant in construction.

- Benefits Realization Management Practice Guide: Focuses on ensuring that project outputs translate into measurable business value and strategic benefits.

- Governance of Portfolios, Programs, and Projects Practice Guide: Establishes frameworks for effective oversight, control, integration, and decision-making across all levels of organizational project management.

- The Standard for Organizational Project Management (OPM): Provides a strategy execution framework to align project management practices with organizational strategy and objectives.

The CQM Manager’s role, as defined within this comprehensive knowledge base, involves overseeing all activities and tasks to maintain the desired quality level, encompassing quality planning, quality assurance, and quality control. This role is pivotal in implementing specific design guidelines and managing processes to achieve an optimal and mature product, ensuring that overall quality objectives are consistently applied across all program components and analyzed for effectiveness.

Construction Project Management Professional (CPMP): The PMI-CP™ Certification

The CQM Methodology operates on the assumption that construction projects are managed by specialized Project Management Professionals equipped for the unique demands of the built environment. PMI has indeed established a dedicated certification for this purpose: the Construction Professional in Built Environment Projects (PMI-CP)™ certification. This certification targets project management professionals with 5 to 15 years of experience, enabling them to acquire and apply specialized techniques tailored for the built environment.

Therefore, the designation of a Construction Project Management Professional (CPMP) under the CQM Methodology aligns directly with the expertise recognized by the PMI-CP™ certification. This signifies a professional who possesses not only general project management competencies (such as those of a PMP) but also a deep understanding and application of construction-specific practices, as detailed in the PMI-CP guidebooks.

CQM BoK References and Specialized Knowledge Areas

The CQM Book of Knowledge is currently under development but will integrate and expand upon the core principles and performance domains of the PMBOK® Guide (Seventh Edition) by incorporating specialized knowledge from the PMI-CP certification training guidebooks. These guidebooks provide targeted expertise critical for quality management in construction, serving as specialized “Knowledge Areas” or domains:

- Construction Project Communications: This domain emphasizes effective communication strategies for complex built environment projects. It involves defining a common source of management information (MI), standardized Key Performance Indicators (KPIs), and appropriate reporting templates to align with project and corporate goals, as detailed in a communications management plan. A key technique is Commitment-based Management™ (CbM), which uses structured conversations to drive actions and outcomes, foster agility, quick decision-making, and build trust through clear commitments, especially in response to emerging risks.

- Construction Scope and Change Order Management: This area focuses on the systematic process of handling alterations or modifications to a construction project’s original scope, plans, specifications, or contracts. It is crucial for documenting, evaluating, and implementing changes during project execution and managing scope creep—the addition of features without addressing impacts on time, costs, and resources. Effective document management, using standardized forms, is essential to ensure stakeholders share a common understanding of changes and decisions, facilitating retrospective analysis of change order causes.

- Construction Interface Management: This specialized domain involves the strategic management of communication, relationships, and deliverables among two or more interface stakeholders to ensure project success. Its primary objective is to foster awareness and efficient management of potential risks at the intersections of responsibilities. Key tools for implementation include the Project Interface Risk Impact (PIRI) matrix and the Interface Complexity Assessment Tool (ICAT) to assess cross-disciplinary coordination and prioritize interfaces. Rigorous configuration management mechanisms are vital to ensure interface documents are updated through various project stages.

- Construction Contract and Risk Management: As the sixth guidebook in the PMI-CP series, this domain integrates robust contract management with comprehensive risk management practices specific to the construction industry. It leverages the principles of risk management in portfolios, programs, and projects to increase the probability of opportunities and decrease the impact of threats. This includes identifying, analyzing, and developing effective response actions for risks, which are critical for navigating the complex contractual relationships and inherent uncertainties in construction projects.

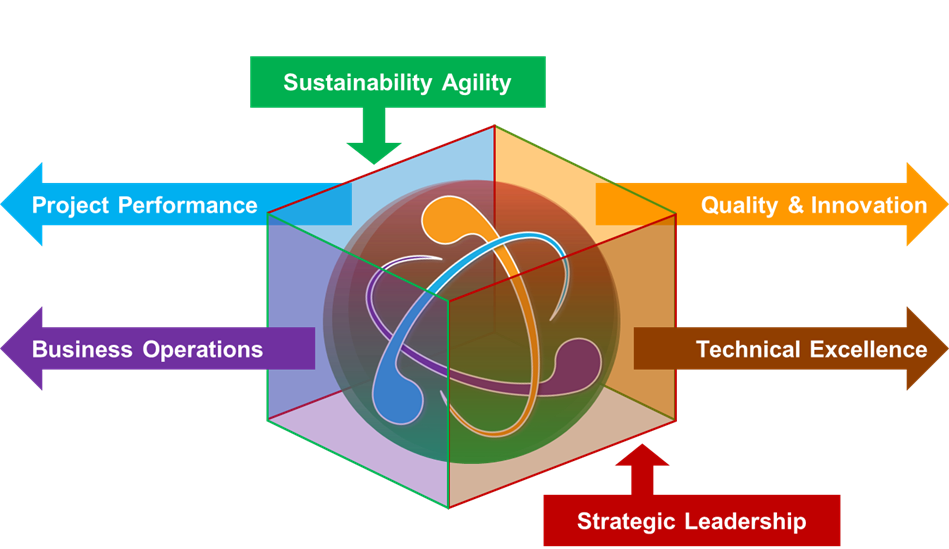

These specialized areas, integrated within a QualityPMO framework, provide the comprehensive context for the CQM Manager’s role. This approach ensures that quality is built into processes and deliverables, risks are optimized, and the organization remains adaptable and resilient in delivering business outcomes. The continuous tailoring of these methodologies to the specific organizational culture and project characteristics is emphasized as a key for successful implementation.

Construction Project Management Professional

The assumption of the CQM Methodology is that the Construction Project is being managed by Project Management Professionals specialized in Construction or as CQM calls them CPMP, Construction Project Management Professionals. PMI has not established a certification based on the Construction Extension, however, a PMP with an understanding of the Construction Extension will qualify as a CPMP as part of the CQM Methodology. In addition, other associations such as CMAA are trying to develop a Construction Project Management Book of Knowledge and Certification program that would have a better understanding and performance within the CQM Methodology than Construction Managers that have not gone through a similar training and certification program.

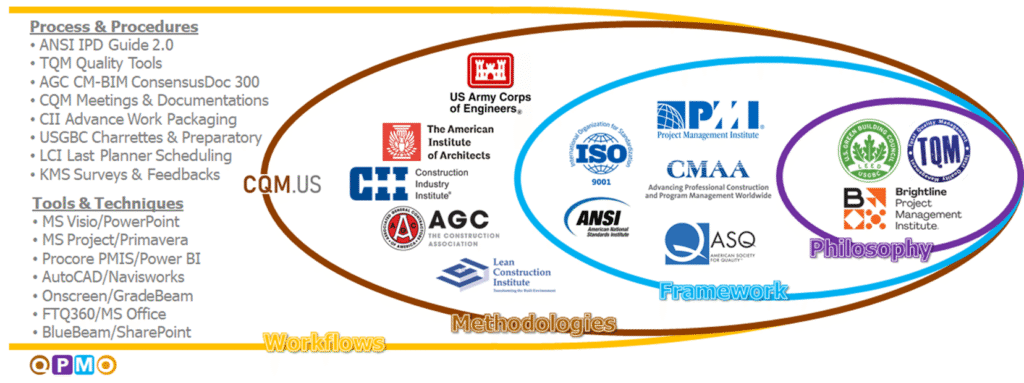

The QPMO methodology is designed as a comprehensive, integrated system to gather and apply best practices and strategies from various construction associations, organizations, and communities of practice, ensuring a holistic approach to quality management in the built environment. This integration forms a coherent system across its Philosophy (🟪Business strategy), Framework (🟦project processes), Methodology (subject matter expertise 🟤), and Workflows (Innovation 🟠), all underpinned by the inclusion of diverse voices and thinking.

🟪 At its core, the Philosophy (business strategy) is shaped by guiding mindsets such as LEED for sustainability, which aligns with project strategies for environmentally friendly and sustainable design using recyclable materials and efficient power supply. Total Quality Management (TQM) principles are integrated through an emphasis on continuous improvement, viewed as an “integrated quality system” embedded across all project activities to meet and exceed customer expectations, requiring senior management support. The Brightline Initiative directly informs the philosophy by bridging the “strategy-to-implementation gap,” ensuring that project execution is purposefully aligned with overarching strategic goals, and it emphasizes understanding and attacking “dysplementation” through systemic paradigms. This foundational philosophy ensures that quality management contributes directly to value creation through improved efficiency, productivity, and organizational transformation.

🟦 The Framework (project processes) is established by governing management systems and standards like ISO 9001 and ANSI, which provide widely accepted voluntary consensus standards for quality assurance and structured management systems. The framework also heavily leverages PMI foundational standards such as A Guide to the Project Management Body of Knowledge (PMBOK® Guide), The Standard for Program Management, and The Standard for Portfolio Management, among others, which define how quality, projects, and programs are structured, measured, and improved. While the query mentions CMAA and ASQ, specific details on their direct inclusion in this QPMO framework were not extensively provided in the sources beyond a general reference to ASQ in a software configuration management context. This robust framework ensures consistent and repeatable processes for managing project constraints like scope, time, cost, and quality, and it explicitly promotes Organizational Project Management (OPM) as a strategy execution framework that integrates portfolio, program, and project management.

🟤 The Methodology (subject matter expertise) draws expertise from industry bodies directly tied to construction methods and delivery practices. USACE (U.S. Army Corps of Engineers) is specifically integrated through its CQM-C program, with the QPMO methodology aligning with and incorporating its requirements and any new government laws and regulations that establish quality standards. CII (Construction Industry Institute) contributes through tools like the Compass diagnostic tool for communications, its Risk Management Process, and its recommendations for Interface Management (IM) implementation. The methodology also incorporates aspects from organizations promoting Lean Construction, such as the Lean Construction Institute (LCI), by emphasizing Lean Thinking principles like eliminating waste and focusing on value, and adopting adaptive and hybrid approaches for project delivery. Although AIA (American Institute of Architects) and AGC (Associated General Contractors) were mentioned in the query as industry bodies, specific details on their direct methodologies (like AGC CM-BIM / ConsensusDocs 300) were not provided in the sources, though the presence of a “Construction Extension to the PMBOK® Guide” implies PMI’s tailored guidance for this sector.

🟠 Finally, the Workflows (Innovation and Digital PMCM) are built upon practical building blocks and digital tools. This includes structured CQM meetings and documentation, involving formal risk workshops, Obeya (“The Big Room”) sessions, and design alignment dialogues to collaboratively problem-solve design-related issues and foster explicit commitments through Commitment-Based Management (CbM). Key documents like quality management plans, risk registers, and interface control documents are managed with rigorous configuration management and stored in centralized information repositories. Digital tools are extensively leveraged, with Project Management Information Systems (PMIS) and Business Intelligence (BI) dashboards (like Power BI) providing real-time visibility, data capture, and early warning indicators for risks. Building Information Modeling (BIM) and Digital Twins are crucial for virtual risk simulations and constructability reviews, enabling early conflict resolution. While specific tools like AutoCAD, Navisworks, On-Screen/GradeBeam, FTQ360/MS Office, Bluebeam, and SharePoint are not explicitly named in the sources, the mention of “field applications,” “collaboration software and tools,” and “Enterprise Resource Planning (ERP) and field-force software tools” indicates the adoption of such digital technologies for enhanced monitoring, data management, and collaboration across the project lifecycle. The emphasis on Knowledge Management Systems (KMS) through surveys and feedback loops further ensures continuous learning, archiving of lessons learned, and the use of historical data for benchmarking and improving future projects.

Together, these layers form a coherent system for delivering construction projects with consistent quality, transparency, and continuous improvement by including diversity and all voices and thinking colors from architects to engineers, facility managers and facility users, business managers to sponsors, and all stakeholders, fostering effective collaboration, addressing cultural differences, and leveraging diverse perspectives to achieve project success and deliver value.

CQM Knowledge Areas

The CQM BoK is under development but will include the PMBoK Ten Knowledge Areas, in addition to Construction Extension’s specific Knowledge Areas as well as few recommended by CQM. The CQM Manager’s role for each of these Knowledge Areas is somewhat explained in this CQM Implementation Handbook, however, there is a need for a CQM Book of Knowledge that would go through each of these Knowledge Areas and clearly define the roles and responsibilities of the Construction Project Manager’s role and the CQM Managers responsibilities.

It’s important to note that while the Project Management Institute’s (PMI) PMBOK® Guide – Seventh Edition has transitioned from ten Knowledge Areas to eight Project Performance Domains and twelve Project Management Principles, the concept of 10 Knowledge Areas is still referenced in other PMI practice guides, such as Process Groups: A Practice Guide, which aligns with your request. The four subsections provided for each Knowledge Area below interpret how construction quality management (CQM) and the Construction Project Management Professional (CPMP) expertise, particularly informed by the PMICP topics, integrate within these traditional areas.

CQM Book of Knowledge: Leveraging PMI Standards and CPMP Expertise

The CQM Book of Knowledge is designed as a structured reference and training resource for all Construction Project Management Team members, ensuring a shared understanding of terminology, processes, inputs, and outputs related to quality management [previous response]. It aligns with and extends PMI’s foundational standards, particularly by integrating specialized knowledge from the PMI-CP certification training guidebooks [previous response].

Here are the 10 Project Management Knowledge Areas, each with four subsections highlighting critical aspects for Construction Quality Management:

1. Project Integration Management

This Knowledge Area focuses on the processes required to identify, define, combine, unify, and coordinate the various processes and project management activities within the Project Management Process Groups.

- Strategic Alignment for Quality Outcomes: Ensuring all project and program efforts align with the organization’s overarching quality strategies and business objectives. This involves a systems-thinking approach to integrate quality goals across the portfolio, program, and project levels to achieve strategic benefits.

- Integrated Quality Management Planning: Developing a holistic project management plan that incorporates and coordinates all quality-related subsidiary plans, baselines, and processes across all project activities. This harmonizes quality efforts with other project management functions.

- Centralized Change Control for Quality Impacts: Implementing a robust system for managing changes to scope, schedule, or cost, with a primary focus on assessing their potential impact on quality and ensuring that only approved, quality-vetted changes are implemented.

- Knowledge Management and Lessons Learned for Continuous Quality Improvement: Systematically capturing, sharing, and applying knowledge from past projects, including quality-related lessons learned, to continuously improve CQM processes and overall project outcomes.

2. Project Scope Management

This area ensures that the project includes all the work required, and only the work required, to complete the project successfully.

- Quality-Driven Scope Definition: Precisely defining the project and product scope, including all deliverables and acceptance criteria, with explicit quality specifications to prevent ambiguity and rework. It also clarifies what is not included in the scope.

- Work Breakdown Structure (WBS) for Quality Control Points: Utilizing the WBS as a foundational tool to hierarchically decompose the total scope into manageable work packages, which then serve as specific points for integrating quality checks, inspections, and verification throughout project execution.

- Construction Scope and Change Order Management: Systematically managing alterations or modifications to a construction project’s original scope, plans, specifications, or contracts. This involves robust documentation, evaluation, and impact assessment on quality to prevent scope creep and ensure quality integrity. (Drawing from PMICP topics)

- Requirements Traceability for Quality Assurance: Maintaining a clear and continuous link from high-level business needs and project objectives to detailed solution requirements and final deliverables, ensuring that all defined quality requirements are consistently addressed and met.

3. Project Schedule Management

This Knowledge Area involves the processes required to manage the timely completion of the project.

- Quality Activity Integration in Scheduling: Embedding specific quality assurance and control activities, such as inspections, tests, quality reviews, and sign-offs, directly into the project schedule and activity definitions.

- Schedule Impact Assessment for Quality Processes: Evaluating how mandatory quality gates, hold points, or potential rework resulting from non-conformance impact the overall project timeline, critical path, and resource availability.

- Change Control for Schedule and Quality: Implementing processes to manage any changes to the project schedule, ensuring that their potential impacts on quality objectives, available time for quality activities, and resource allocation are thoroughly assessed and controlled.

- Performance Metrics for Schedule Quality: Utilizing key performance indicators (KPIs) and reporting mechanisms to track schedule adherence and identify potential delays or accelerations that could negatively impact quality (e.g., rushed work leading to defects or insufficient time for thorough testing).

4. Project Cost Management

This area includes the processes involved in planning, estimating, budgeting, financing, funding, managing, and controlling costs so that the project can be completed within the approved budget.

- Cost of Quality (CoQ) Planning: Systematically estimating and budgeting for all costs associated with preventing poor quality, appraising quality, and remediating internal or external failures. This ensures a proactive approach to quality costs.

- Earned Value Management (EVM) with Quality Indicators: Employing Earned Value Management as a robust methodology to integrate cost, schedule, and scope performance, extended to include quality parameters and the financial implications of quality deviations or successes.

- Budgeting for Quality Assurance & Control Resources: Allocating dedicated financial resources for the necessary personnel, equipment, materials, and processes essential for maintaining and verifying project quality throughout its lifecycle.

- Financial Risk Analysis of Quality Non-Conformance: Conducting thorough analyses of potential cost overruns, claims, and penalties that could result from poor quality, defects, or failure to meet specified quality standards.

5. Project Quality Management

This Knowledge Area incorporates the organization’s quality policy regarding planning, managing, and controlling project and product quality requirements.

- Defining Quality Standards and Requirements for Construction: Establishing specific, measurable quality standards, metrics, and acceptance criteria uniquely relevant to the built environment, including adherence to regulatory requirements and stakeholder expectations.

- Quality Assurance Process Implementation: Ensuring that all established quality processes, standards, and methodologies are rigorously followed throughout the project lifecycle to prevent defects, ensure consistency, and build confidence in deliverables.

- Quality Control Measurements and Inspections: Performing regular and systematic measurements, inspections, and testing of construction deliverables and work products against defined quality standards and acceptance criteria.

- Continuous Quality Improvement and Lessons Learned Integration: Implementing continuous feedback loops, conducting root cause analysis for identified non-conformances, and integrating lessons learned from quality audits to constantly enhance quality processes and outcomes.

6. Project Resource Management

This area describes the processes to identify, acquire, and manage the resources needed for the successful completion of the project.

- Competency-Based Staffing for Quality Roles: Identifying and acquiring human resources with the necessary specialized skills, experience, and certifications (e.g., PMI-CP) for critical quality management roles and tasks in construction.

- Training and Development for Quality Skills: Providing ongoing training, mentorship, and professional development opportunities to enhance the project team’s quality management competencies, awareness, and commitment to quality standards.

- Strategic Allocation of Quality Resources: Optimizing the deployment of all resources (human, material, equipment) to quality-critical activities, ensuring adequate support for effective quality control, assurance, and inspection efforts.

- Management of Physical Resources for Quality Standards: Implementing robust processes to ensure that all materials, tools, and equipment procured and used on-site meet specified quality standards, are properly stored, handled, and maintained to prevent degradation or damage that could impact project quality.

7. Project Communications Management

This Knowledge Area includes the processes required to ensure timely and appropriate planning, collection, creation, distribution, storage, retrieval, management, control, monitoring, and the ultimate disposition of project information.

- Construction Project Communications Strategy: Developing a comprehensive communication plan specifically tailored to the complex needs of construction project stakeholders, emphasizing clarity, frequency, and appropriate channels for sharing quality-related information. (Drawing from PMICP topics)

- Commitment-Based Management (CbM) for Quality Accountability: Utilizing structured conversations and clear commitments to drive accountability for quality outcomes, foster agility, enable quick decision-making, and build trust among team members and stakeholders, especially in response to emerging quality risks.

- Performance Reporting and Digital Dashboards for Quality: Establishing and utilizing digital dashboards and standardized reports to disseminate clear, timely, and actionable quality performance data (e.g., KPIs, defect rates, inspection results), providing real-time visibility for decision-making.

- Stakeholder Feedback and Engagement for Quality Improvement: Creating formal and informal mechanisms for collecting, analyzing, and responding to feedback from all stakeholders regarding project quality, fostering a collaborative and transparent approach to continuous improvement.

8. Project Risk Management

This area includes the processes of conducting risk management planning, identification, analysis, response planning, response implementation, and monitoring risk on a project.

- Construction Contract and Risk Management Integration: Systematically identifying, analyzing, and responding to multifaceted risks inherent in construction projects, particularly those related to contractual relationships, quality clauses, potential claims, and uncertainties. (Drawing from PMICP topics)

- Quality Risk Identification and Analysis: Proactively identifying potential threats to project quality (e.g., material defects, design errors, craft deficiencies, environmental impacts) and opportunities for quality enhancement, including their probability and impact.

- Risk-Based Quality Response Strategies: Developing and implementing specific strategies and actions to mitigate identified quality threats and capitalize on quality opportunities, integrating these responses with overall project risk management plans.

- Monitoring and Control of Quality-Related Risks: Continuously tracking identified quality risks, implementing planned risk responses, and evaluating their effectiveness throughout the project lifecycle to ensure quality objectives are met despite uncertainties.

9. Project Procurement Management

This Knowledge Area includes the processes necessary to purchase or acquire products, services, or results needed from outside the project team.

- Quality Requirements in Procurement Documents: Ensuring that all contracts, requests for proposals (RFPs), and other procurement documents clearly define the necessary quality standards, specifications, and acceptance criteria for all goods, materials, and services to be acquired.

- Supplier/Contractor Quality Capability Assessment: Developing and applying rigorous criteria to evaluate and select potential vendors and contractors based on their demonstrated ability to meet specified quality requirements, past performance, and quality management systems.

- Quality Assurance of Procured Items: Implementing systematic processes, such as inspections, audits, and testing, to verify that purchased materials, components, and services conform to contractually defined quality standards before they are integrated into the project.

- Contractual Compliance and Performance Monitoring for Quality: Continuously monitoring vendor and contractor performance against the quality clauses in their contracts, and effectively managing any non-compliance issues or quality-related claims.

10. Project Stakeholder Management

This Knowledge Area includes the processes required to identify all people or organizations impacted by the project, analyze stakeholder expectations and their impact on the project, and develop appropriate management strategies for effectively engaging stakeholders in project decisions and execution.

- Stakeholder Identification and Analysis for Quality Impacts: Identifying all internal and external stakeholders (e.g., project owner, contractors, subcontractors, regulatory bodies, end-users, community members) who can influence or are affected by project quality, and assessing their interests, expectations, and potential impact.

- Engagement Strategies for Quality Expectations: Developing and implementing tailored plans to effectively engage stakeholders, ensuring alignment on quality objectives, managing expectations, and fostering their commitment to achieving desired quality outcomes.

- Managing Stakeholder Perceptions and Buy-in for Quality: Proactively communicating quality progress, addressing concerns, and resolving conflicts to foster a shared understanding, trust, and active support for the project’s quality deliverables and overall performance.

- Feedback Mechanisms for Stakeholder Quality Satisfaction: Establishing clear and accessible channels for continuous feedback from stakeholders regarding their satisfaction with project quality, and incorporating this feedback for iterative improvements and adaptive responses.

Construction Project Management Professional (CPMP) Specific Topics

The QualityPMO System employs a highly integrated, multi-phase approach to elevate construction project outcomes. Construction Quality Management (CQM), primarily the focus of Phase 2, is intricately linked with the broader responsibilities of a Construction Project Management Professional (CPMP) and interfaces upstream with Design Quality Management (DQM), which focuses on Phase 1: Project Definition & Planning and Design & Engineering. DQM ensures “buildable quality” through establishing design quality criteria, facilitating design quality reviews, and performing digital model checks like clash detection and specification compliance, creating a crucial feedback loop where construction lessons inform engineering for continuous improvement.

The core of CQM lies in the Construction & Execution (Phase 2), encompassing all Quality Assurance (QA) and Quality Control (QC) activities. This includes augmenting the contractor’s own QC processes (CQC) with owner’s QA oversight, implementing Inspections and Test Plans (ITPs), and managing non-conformances. The system emphasizes proactive prevention over reactive inspection by leveraging Digital PMCM, Building Information Modeling (BIM), and AI-driven analytics for continuous monitoring and adaptive responses to real-time risks. Technologies such as BIM-enabled issue tracking, mobile field applications for logging Non-Conformance Reports (NCRs) and RFIs, and PMIS analytics provide predictive alerts and enhanced monitoring of physical resources and work performance, directly integrating quality into work processes and even embedding “Stop Work” authority within quality procedures.

This rigorous oversight then directly ties into the Facility Operation & Maintenance (Phase 3), ensuring a seamless transition to Facility Management. This involves laying the groundwork during Phase 2 to transition quality information to operations, defining how asset data, as-built models, warranties, and maintenance plans are handed over to facilities management teams, aligning with ISO 55000 and ISO 41001 principles for lifecycle quality. A digital twin of the asset is delivered, providing an up-to-date 3D model reflecting all changes, with equipment data, manuals, and quality records attached. This digital twin is invaluable for commissioning walk-throughs and provides traceability of all QA/QC records to final assets, enabling post-handover monitoring of asset performance through BI4FM dashboards and closing the feedback loop by informing future design and construction methodologies.

These specialized areas provide the context for the CQM Manager’s role in overseeing and ensuring quality throughout built environment projects, aligning with the principles of the QualityPMO framework for adaptable and resilient delivery of strategic outcomes.

CQM Inputs and Outputs

In enhancing the understanding of Construction Quality Management (CQM) Methodology, it’s crucial to detail how the Inputs, Tools, Techniques, and Outputs (ITTO) framework, prominent in A Guide to the Project Management Body of Knowledge (PMBOK® Guide) – Sixth Edition, is applied. In PMBOK® Guide – Sixth Edition, project management processes were defined by their ITTOs, where specific inputs (e.g., project management plans, project documents, organizational process assets) are transformed into outputs (e.g., deliverables, plans, reports, updates to other documents) by applying various tools and techniques. This systematic flow is fundamental: an output from one process (e.g., “Verified deliverables” from the Control Quality process) frequently becomes an input for a subsequent process (e.g., “Verified deliverables” becoming an input to the Validate Scope process for formal acceptance).

For a process like Plan Quality Management in PMBOK 6, inputs would include the project charter, requirements documentation, and risk register. Tools and techniques such as data gathering (benchmarking, brainstorming, interviews) and data analysis (cost-benefit analysis, cost of quality) are applied. The outputs are the Quality Management Plan and Quality Metrics. Subsequently, the Manage Quality process uses the Quality Management Plan as an input, applying tools like audits and process analysis, to produce Quality Reports, Test and Evaluation Documents, and Change Requests. Finally, the Control Quality process, taking deliverables and work performance data as inputs, uses inspections and testing to produce Quality Control Measurements and Verified Deliverables.

Applying this ITTO logic to CQM Methodology means that, as stated, every document generated as a defined Output from a CQM process (e.g., a quality report or verified deliverable) becomes an Input in subsequent processes after specific Tools and Techniques are applied to generate new outputs. For instance, the Apply CQM Process Flow Chart would visually represent these continuous feedback loops and iterative cycles, showcasing how CQM processes integrate with other project management processes like scope, schedule, cost, risk, communications, resource, and stakeholder engagement.

The distinction where CQM is defined as both a methodology and a framework implies a more prescriptive approach compared to PMBOK® Guide, which traditionally served as a “standard” or “guide” describing “what” constitutes good practice. However, PMI’s “practice standards” do “provide more explanations, specifications, and in-depth experience-based knowledge about a topic and its implementation,” conveying “both the what and recommended how”. An Organizational Project Management (OPM) methodology, for example, is specifically tailored to an organization’s background, circumstances, motives, and needs, providing advice and instructions. This aligns with the user’s vision for CQM.

This approach means that the CQM Implementation Handbook, as it is developed, will suggest specific Tools and Techniques to be used, along with the why, when, how, and by whom they should be applied, grounded in a clear purpose. The CQM Book of Knowledge (BoK) will function as a living document, serving as a critical Organizational Process Asset (OPA), continually updated with lessons learned, historical performance information, benefits realization data, and aggregated risk management effectiveness related to quality. This facilitates knowledge management and ensures that prior organizational knowledge is leveraged for continuous improvement and better project outcomes. The integration of adaptive and iterative approaches and the adoption of digital technologies (like PMIS, BIM, and digital twins) further enable the inclusion of new innovative solutions and best practices, making the CQM BoK a dynamic and evolving resource for continuous growth and sustained competitive advantage.