CQM Documentations required as part of the CQM Framework to ensure an integrated quality management system are based on workflow and information knowledge management requirements.

The number of these Documentations might seem overwhelming and a waste of time for top Quality Managers and Quality Directors. However, the CQM Methodology is a robust system where components are preserved but methods are customized as Lean as possible to the need and requirements of specific organizations and their Construction Projects.

Best Practice for CQM Documentations

CQM required Documentations are essential to the success of the CQM Program, therefore they cannot be deleted or ignored. However, depending on the size of the organization and construction project, many of these Documentations could be grouped in Reports, Meeting Minutes and Email Communications.

For example, a Quality Preparatory Meeting is necessary to be documented, but not all discussions need to be recorded. Since much of the discussions are confirming previous Project Management Planning, the Quality Preparatory Meeting Minutes will cover Meeting information on Time and Location, Attendance, and major issues and conflicts that were discussed and resolved. The Quality Preparatory Meeting is not intended to change any contract requirement, therefore any newly discovered issues must be sent back to the Change Process as a new RFI and receive formal approvals.

CQM Documentations

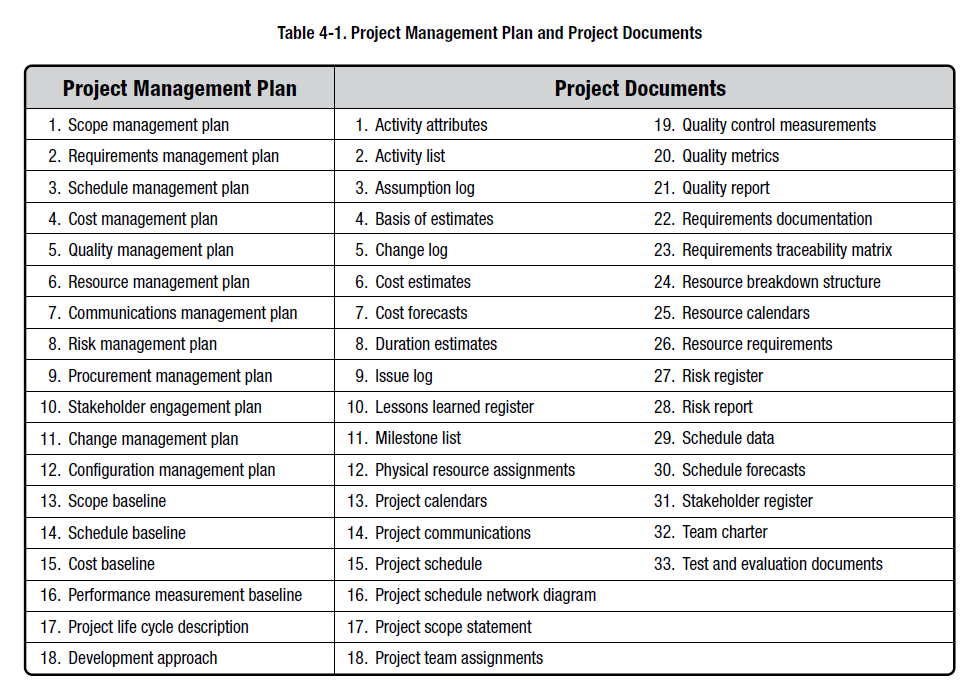

As mentioned before, CQM Methodology is based on PMBoK Framework with adjustments and improvements considering Project Management Professionalism and Business Administration Best Practices. In addition, CQM Methodology will include the CMAA CQM Documentation recommendation and applies the LEAN Construction Best Practices to Quality Manager’s role for each meeting and document review and approval.

CQM Documentations that are part of an Integrated Quality Management for a Construction Project Management Professional quality performance is listed below. These documents are prepared by various members of the Quality Management Team i.e. Project Manager, Project Superintendent and Project Engineer and it is recommended that a Quality Manager dedicated to the Project participates in the development of these documents or at least have access to them for better CQM Implementation. At a minimum, items that are highlighted with bold lettering should be assigned to the Quality Manager:

Pre-Construction Documentations

- Stakeholder Registry

- Pre-Qualification Review Forms

- Supply Chain Scorecard Reports

- Assumption Log & Change Log

- Project Life Cycle Description

- Sustainability & LEED Requirements

- Development Approach & Integrated Project Delivery

- Contract Specifications & Requirements

- Contract Drawings

- Contract Documents

- Project Owner Milestones

- Risk Management Plan

- Dispute Avoidance and Resolution

- Risk Registry & Updates

- LEAN Project Management Plan

- Communication Plan

- Cost Analysis & Project Feasibility Studies

- Value Engineering Reports & Constructability Reviews

- Work Breakdown Structure (WBS)

- Definable Features of Work List

- Basis of Estimates & Detail Cost Breakdown (DCB)

- Resource Assignments & Project Team Assignments

- Project Calendar & Duration Estimates

- Schedule of Value (SOV) & Cost Forecasts

- Project Charter & Team Charters

- Pre-Bid Conference & Walkthrough Agenda

- Request for Information Log & Requirement Traceability Matrix

- Permits, Insurance, Labor Affidavits, and Bonds

- Letter of Intent & Notice to Proceed

- Kick-off Meeting Agenda & Meeting Minutes

Construction Documentations

- Stakeholder Engagement Plan

- Risk Management Plan

- Documentation of Existing Conditions

- Risk Report

- Scope Management Plan

- Scope Baseline & Requirements Traceability Matrix

- Submittal Register, Transmittal Form, and Log

- Schedule Management Plan

- Schedule Baseline & Construction Schedule

- Cost Management Plan

- Cost Baseline & Construction Budget

- Cash Flow & Contingency Plans

- Progress Payment & Pay Applications

- Earned Value Management

- Performance Measurement Baseline

- Status Updates and Progress Reports

- Resource Management Plan

- Resource Breakdown Structure (RBS) & Calendar

- Procurement Plan & Supply Chain Management (SCM)

- SCM Solicitation & Information to Bidders

- Bid Opening and Evaluation

- Buy-outs and Trade-off Value Analysis

- SCM Notice to Proceed

- Pre-Construction Conference & SCM Kickoff meeting

- SCM Permits, Insurance, Labor Affidavits, and Bonds

- Advance Work Packages & Installation Work Packages

- Construction Coordination and Kick-off Meeting Minutes

- Pull Planning & LEAN Best Planner Scheduling

- Master Schedule, Six-Week, Three-Week Schedules

- BIM Coordination Meeting Minutes

- BIM Conflicts and Clash Reports

- Requests for Information and Log

- Corrective Actions & Punchlists

- Change & Configuration Management Plan

- Claims Mitigation and Evaluation

- LEAN A3 Problem Solving Tracking & Value Stream Mapping

- LEED Quality & Environmental Management Manual

- Site-Specific Quality Plan & Quality Control Checklists

- Health, Safety, Security, Environment HSSE Manual & Plan

- Safety and Quality Orientation and Onboarding Sign-in Sheets

- Daily safety inspections & Activity Hazard Analysis (AHA)

- Inspection, Testing & Evaluation Documents

- Quality Metrics & Control Measures

- Quality Performance Areas KPA & Indicator Metrics KPIs

- Quality Phase Preparatory Meeting Minutes & Sign-in Sheets

- Quality Observation Photos & Reports

- Deficiency and Rework Items List

- Quality Incident Reports

- Quality Non-Conformance Report

- Quality Activity and Audit Visits Log

- Plan of Day Plan & Kaizen Events

- Daily Field Reports & Daily Resource Report

- SCM Production Reports & Inventory

- Long Lead Material & Delivery Dates

- Inventory & Production Site Visit Reports

- Update Documents & Record Drawings

- Pre-start Tests and Commissioning Meetings Minutes

- Punchlist Walkthrough and IWP Closeout Workshops

- Training and Handover Meetings

- Substantial Completion

Post Construction Documentations

- Close-out Procedures

- Kaizen and Daily Continous Improvement Reports

- Updated Issue Log & Lessons Learned

- Maintenance and Operation Manuals

- Spare Parts & Warranties

- Commissioning and Handover

- Claims Resolutions

- Final Permits and Certificate of Occupancy

- Lessons Learned Collection and Knowledge Management

- QMS Review and Updates

- Contractor Closeout

- Final Acceptance & Final Payment

- Project Closing Celebration

CQM.US Consultants

Overwhelmed by the amount of CQM Documentation Requirements? Ask a CQM.US Expert how a CQM Implementation plan could be customized to your organization or project’s need to gain the most value of the CQM Methodology and Framework.