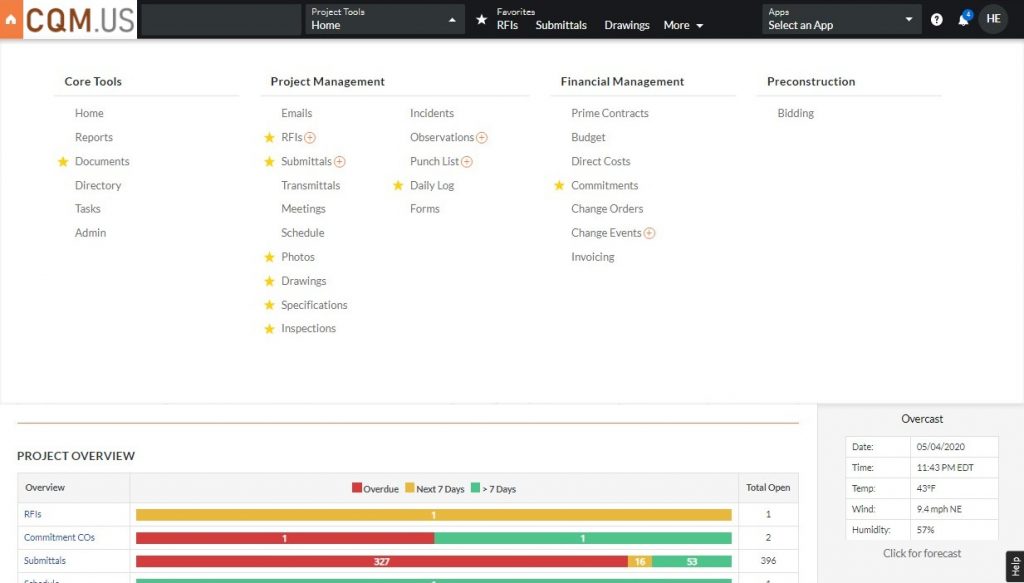

Use of a Project Management Information System such as Procore PMIS for CQM Implementation as a tool is the key to successful documentation and proper workflow automation. There is a variety of selection for PMIS systems available in the market for the Construction Industry, however, Procore is selected due to its ease of use, quick customization, efficient user learning process with many available resources, and excellent customer support.

Procore Modules

Although Procore has many different Modules and Integrations available for use, the focus of the Apply CQM Process is the Project Management Module and Documents Core Tool to properly document Quality-Related documentation and workflows.

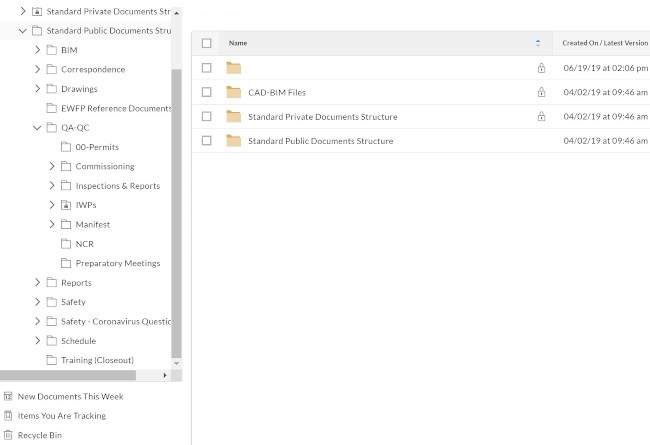

Documents Structure

The Construction Project Management Team must realize that they are all part of the Quality Team and their project documentation is critical to creating a thread and trail to discover root causes in case corrective action is required. Therefore, the proper Document Structure is needed initially as the project is defined in the PMIS system where Quality-Related Documentations such as Coordination, testings, Meeting Minutes, and Follow-ups are tracked and stored for future reference.

The advantage of using Procore is that every document is accessible in the web browser, downloadable, with unique web and email tracking address for follow up and reference. Procore has a strong distribution feature with notification of newly uploaded documents. In addition, features such as showing all “new documents uploaded this week” and “items you are tracking” are just a click away.

There is also a great customizable feature for permission and access limitation setting that could categorize documents for proper stakeholders. All project stakeholders will get access to the documents to feature with unlimited cloud space through the one subscription, so there is no need for concern with large files or uploading updates to files as Procore’s built-in Document feature will take care of all version tracking and backups automatically. Therefore, the project team must familiarize itself with the Procore Documents system and avoid storing documents on personal computers and various cloud locations.

Procore PMIS for CQM Process

The Submittal and RFI reviews are part of a proper Quality Management for a Construction Project, however, they are mainly handled by the Project Engineering and the CQM Manager will use this section for Reviews and preparing for the Quality Preparatory Meetings. The same goes for the Drawings and Specifications section of Procore PMIS. Some features such as Meetings and Transmittals are shared between Project Coordination and Quality Management, it is highly recommended that the Quality Manager uses the great Procore Meeting Feature, however since the Quality Meetings are not in a series such as a weekly coordination meeting, it might be difficult to fit all the information provided on the Quality Preparatory Meeting Minute on the Procore Meeting Format. None the less, the Procore Customer Support and Customization Team could help a large organization to modify the standard format to fit the need of an organization.

Procore Features for CQM

The main focus of this section is to introduce Procore PMIS for CQM as a tool for Quality-Related Documentation and Workflow. These features are as follows but are not limited to:

- Photos

- Inspections

- Incidents

- Observations

- Punch List

However, for the optimized and Lean approach use of Procore for Quality Management, CQM recommends the following as best practice:

- Photos: Quality Manager should make frequent if not daily visits to the job site and record his inspections as a photo diary in a separate folder from Daily Reports and Safety Inspections. Photos should provide a clear storyline of before, during, and after work progress of the activity as well as the surrounding area. It is recommended to use a timestamp and location stamp software on the phone or tablet such as Solocator to keep track of each photo location and time. It is best to load the photos as soon as they are taken with further commenting by the QM on what is being photoed for future reference.

- Inspections: Load QC Checklists as soon as a Site-Specific Plan is developed per specification sections and DFoW. Quality Manager is to create an Inspection Report on a periodic basis and confirm that the subcontractor’s work is being performed accordingly. The subcontractor may use this feature or upload field checklists in the Documents Folders. Creating Inspection Template in Company Level is recommended for a large organization performing similar projects.

- Observations: Create an Observation report as soon as an issue does not meet the Quality Expectation as a Quality Incident. The Observation Report should accompany a photo of the issue and assign the corrective action to the responsible party with a due date. If the Quality Incident requires an Architect input for a solution to modify Contract Documents or Design Records through an RFI process, it must be recorded as a Non-Conformance Report.

- Punch List: Corrective items that would not be corrected before a certain period or will require additional tasks and activities to be completed prior to rectifying the situation will be required to be recorded as a Punch List item for future action as to not forget and miss the activity.

- Incidents: The Apply CQM Process has no use for this feature and as part of its Lean approach recommends avoiding the use of too many similar features if possible to reduce waste, redundancy, confusion for users and speed of entry.

Procore Business Intelligence for CQM

The Procore PMIS system has a customizable reporting and dashboard display options to take information from mobile and tablet straight to a manager’s desktop for faster and better decision making. In addition, Procore has great integration capability to integrate other more sophisticated and specialized apps within its platform that an organization must consider depending on the size and type of construction projects it performs. Although CQM Methodology associates Quality with Risk Management and handles Safety Separately, the Procore feature is called Quality and Safety Module. It is the Organization’s responsibility to create clear Process and Procedures with Flowcharts to define how they use the Procore Features, especially when adopting the CQM Framework and Methodology. All that said, below is a short demonstration of the Procore Quality Safety Product Demo: