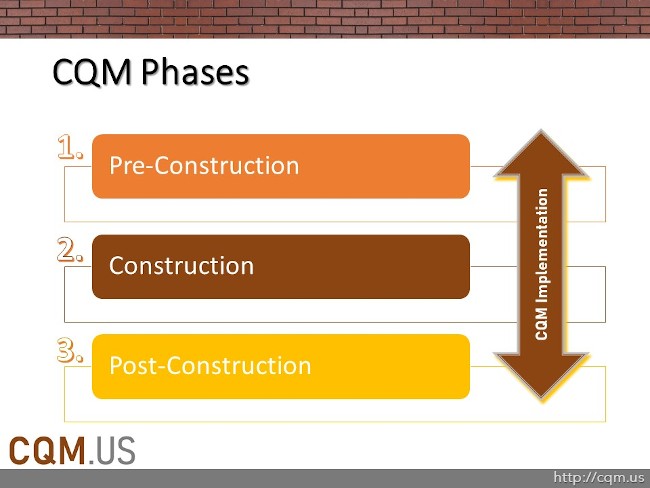

Understanding the CQM Phases will help to comprehend the need for a Quality Management Mindset in different phases of a Construction Project.

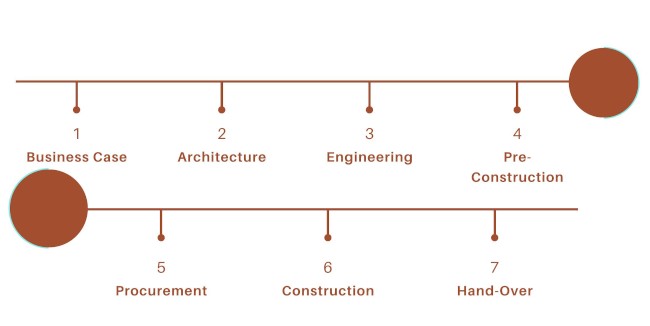

Depending on a role of a Construction Project Stakeholder, whether it is Business Manager, Developer, Regulator, Legal Console, Architect, LEED Expert, General Contractor, Subcontractor, Inspector, Supplier, Project Manager, BIM Modeler, Scheduler, Quality Manager, Engineer, Technician or Laborer each entity has its own perspective on Construction Project Phases depending on its accountability and responsibilities.

To simplify the understanding of Construction Project Phases, CQM Phases are developed and defined with a LEAN Mindset in the CQM Framework.

CQM Phases

CQM Phases as it relates to Construction Quality Management is divided into three:

- CQM Phase in Pre-Construction period when the Sponsor is incubating a concept with the help of consultants and Architects

- CQM Phase During Construction is when the Design has been Developed for a General Contractor to bring it to life and physically construct the concept

- CQM Phase of Post-Construction is when the Concept has reached its goal and maturity by achieving the Construction Project’s Output for the desired Business Outcomes ready for Operation

However, in an Integrated Project Delivery approach, these phases might overlap and be customized to the need of the team. CQM Methodology recommends Integration of Quality from an early stage and here is how it is possible:

CQM Phase in Pre-Construction

It is customary for a Construction Project Team to form after an initiative started from a Business Case and Concept. The sponsors of the Business Case will designate a team to hire the Architect to bring the concept to life. These Requirements collection meetings are best performed when a Project Management Professional is onboard. USGBC also recommends that a LEED expert be included on the team from this stage! This team will be known as the Owner of the Construction Project.

Upon completion of the schematic design and sponsor’s approval of the initial design documents, Engineers are hired to design the product for production. CQM recommended Integrated Project Delivery (IPD) best practice suggests that a Construction Manager is on board at this stage to help with the constructibility evaluation, value engineering, and cost estimation.

Upon completion of the Design Development drawings and specifications, a Pre-Construction Meeting is held to obtain feedback from Prime Contractors and Specialty Subcontractors. CQM recommends that the Construction Manager be the responsible entity to hold these meetings and involve a Quality Manager at this stage to plan, coordinate, execute, and monitor quality control and assurance activities.

Upon completion of the Pre-construction Design changes through Request for Information and generated Addendums to the Design Documents, the Architect finalizes the Scope Baseline with the Construction Documents labeled as Issued for Construction Drawings and Specifications. This Scope Baseline will be the foundation of Work Breakdown Structure (WBS) and Definable Feature of Work (DFoW) that would form the Cost and Schedule Baseline. Any changes after this stage will be issued as Bulletins and Engineering Construction Notes that would significantly impact the cost and time of the project completion.

CQM Phase During Construction

The Construction phase starts after the issuance of the Letter of Intent and Contract Award with a Kick-off Meeting. In the kick-off meeting, Owner’s expectations are reminded before start of work, and CQM Methodology recommends a Quality Orientation meeting with every Subcontractor and Major Supplier as part of the project onboarding process. The Advanced Work Packaging (AWP) system is introduced and an Installation Work Package (IWP) coordinator is assigned. A Construction Project Management Professional understands that this is the perfect time to build team momentum for quality culture and quality excellence mindset. Introduction of the Quality Manager and demonstrating the value and importance of a Quality Manager’s role at this stage is the perfect time to signify the organization’s core value and commitment to Quality!

Any other meetings from this point on in the Construction Project is part of the Construction Quality Management Program. The Quality Manager assists the Project Manager and Project Engineer to create the Installation Work Packages according to the agreed DFoW and WBS and will have them ready six weeks ahead of construction installation start. Lean Construction’s Pull Planning is used to call upon the supply chain to attend a Quality Preparatory Meeting after the approval of the IWP package. During the meeting, IWP information is confirmed with all stakeholders’ attendance to reiterate quality requirements and expectations. The IWP includes list of applicable reviewed and approved Construction Documents, RFIs, Submittals, Shop drawings, Schedule, Safety Procedures and Activity Hazard Analysis (AHA), and Quality Control and Assurance requirements and expectations.

As part of the IWP package, a BIM visualization of the work activity and CPM Schedule is required. Therefore, BIM coordination meetings and Scheduling meetings are also part of Quality Control and Assurance by the CPMP team. CQM Methodology recommends that the Quality Manager be part of all these meetings and in absence of the Construction Project Manager, lead and direct the meetings for better performance and scope implications that might occur during the discussions. These weekly meetings with all Subcontractors and Suppliers will ensure that everyone is coordinated and clashes are detected ahead of construction time. Questions and concerns generated from these meetings will be forwarded as RFIs to the A/E for review and approval after Quality Manger’s review.

CQM Methodology recommends holding Workshop Meetings for discussions that would take more than 10 min in any meeting or phone conference. Workshop Meetings will be planned for the future and will give all stakeholders a chance to participate with a clear agenda and fully prepared to contribute to the problem-solving session, therefore, creates a teamwork culture, partnership mindset, and team buy-in of the final decision!

After the Quality Preparatory meeting, the Subcontractor is onboard and should attend the daily Plan of the Day (PoD) meeting. The PoD meetings are similar to Stand-up meetings in Scrum’s Agile Project Management Best Practice, where foremen of all active subcontractors will gather with the Construction Project Management Team to report yesterday’s updates, review today’s activities, and coordinate tomorrow’s work. The PoD meeting should not take more than 15 minutes and the meeting notes should be published to all stakeholders no later than an hour after the meeting.

This is where Quality Manager’s Traditional Quality Management System (QMS) starts to work. The Quality Manager will plan his work to observe and inspect as work is being performed in Inspection Reports and Quality Observation Reports with extensive Photography of the progress. All work that is out of specified scope and requirements must be reported as either Quality Incident Reports or Non-Conformance Reports. A Quality Log is generated with all observations and Quality Activities for Weekly and Monthly reporting and knowledge management of Lessons Learned.

CQM Methodology recommends daily Quality Quotes mentioned with Safety word of the day in the beginning of PoD meetings. Weekly Quality Talks, similar to Tool-Box Meetings, will remind everyone to think Safety First-Quality Always mentality. The Quality Manager should be able to talk to all subcontractors and their team members similar to a Safety Manager would remind everyone of their expected behavior and requirements.

The Quality Management Team will surprise visit workshops and plants to confirm quality products and performance as part of their Risk assessment. As part of these visits, Factory Testing are witnessed, inventory is checked and scheduled deliveries are confirmed.

CQM Phase of Post-Construction

Quality Walk-throughs and Quality Audits are major steps in the success of the CQM Methodology QMS system. On a periodic basis, the Quality Managers of different stakeholder representatives will gather to walk the Jobsite and help in identifying Quality Measures that are not obvious in the contract documents. The owner’s Quality Manager will audit the Prime Contractor’s QMS to make sure all Quality Documentations and Control Checklists are up-to-date on the PMIS and available in the Jobsite.

The Start-up meetings and Commissioning will be coordinated by the Quality Manager in the CQM Methodology. The quality point of contact for the Construction Project Management Team is the Quality Manager. All Opertion and Maintenance Manuals are collected, As-Built drawings are finalized, Quality Assurance reviews and verifications are completed, before a finalizing and closing the IWP.

Punchlist walkthroughs should be very smooth in the CQM Methodology. A major money-draining phase of construction projects is the Punchlist phase after the Substantial Completion. Here is where CQM Methodology will show its value and effectiveness by reducing the time and effort to pass the Final Inspection and Owner’s Acceptance. Since all IWPs were closed during the construction operation, there is no need for additional effort and mobilization cost to correct issues, and since preventive and proactive measures were taken during the QMS process, no major quality issues should be detected during the Final Inspection Phase.

CQM.US CQM Coach

CQM.US Experts are professionals understand the importance of a Quality Manager in different CQM Phases in the success of the CQM Implementation. Please seek a CQM Expert’s consultation to better customize the Construction Project Management with Integrated Quality Management for your Construction Projects from the beginning by applying CQM Methodology in the early stages of Contract Documents development.

CQM Training

CQM.US Experts have developed a CQM Methodology that integrates Quality Management in all Construction Project Management and Business Administration areas. For the proper CQM Implementation don’t hesitate to contact us for more details to customize the Apply CQM processes to your organization.