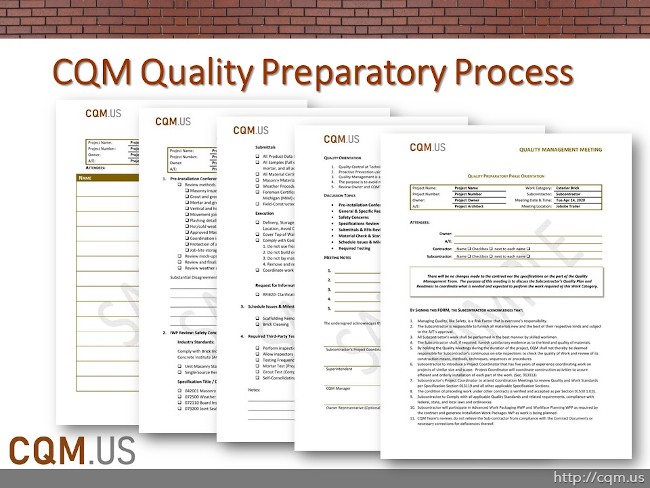

The CQM Quality Preparatory in CQM Methodology is a process rather than just a meeting. The Quality Preparatory Meeting is part of the process after the information is collected and CQM Manager‘s review and understanding are confirmed with all the Construction Project stakeholders.

In this section, a practical step by step instruction to perform the CQM Quality Preparatory Process is offered as a best practice.

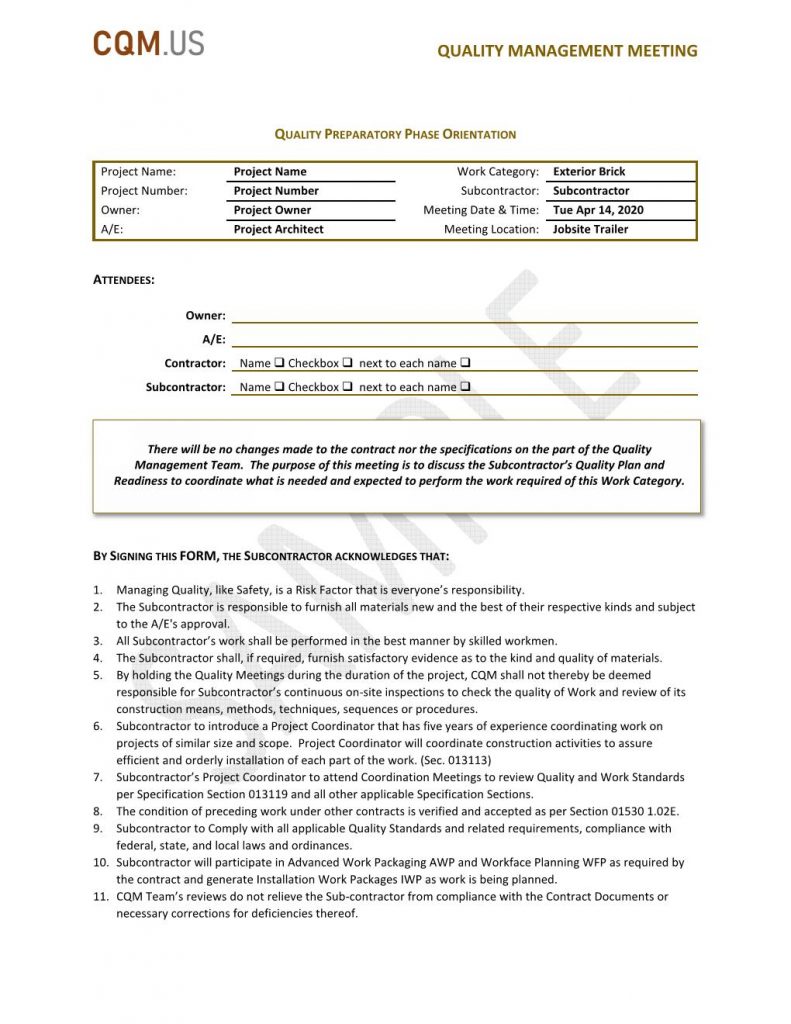

Quality Preparatory Meeting

Similar to the traditional Quality Preparatory Meeting in the USACE CQM-C methodology, the Quality Preparatory phase is performed prior to beginning work on each definable feature of work (DFoW) and is held as a meeting with a checklist of items to be verified. However, since the Advance Work Package system is used by the CQM Methodology, part of this work is accomplished during the preparation of the Installation Work Packages (IWP) for each DFoW. Therefore, the Quality Preparatory Meeting in the CQM Methodology is more similar to the Initial Phase were it is held a minimum of two weeks before the beginning of a DFoW which might consist of several IWP packages.

Quality Preparatory Attendees

It is mandatory for the Subcontractor and related suppliers to attend the meeting in person with CQM Manager, Project Manager, Superintendent and Project Engineer. The Owner, A/E, and Third-party Testing representatives are notified two weeks ahead of the meeting are invited to the meeting but their attendance is optional.

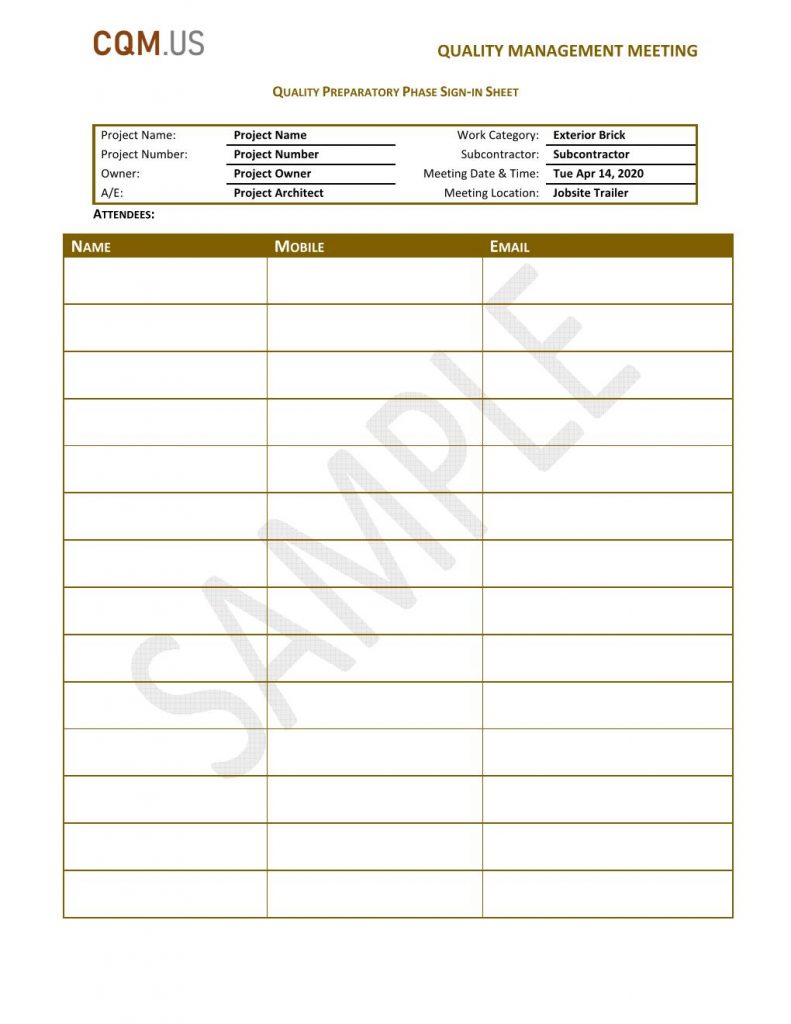

The most important part of this section is to fill in a Meeting Sign-in Sheet and keep track of the invitation sent and keep a record of the notification date, invited guests, attendees, and date of the meeting as part of a Construction Project Management Professional requirement.

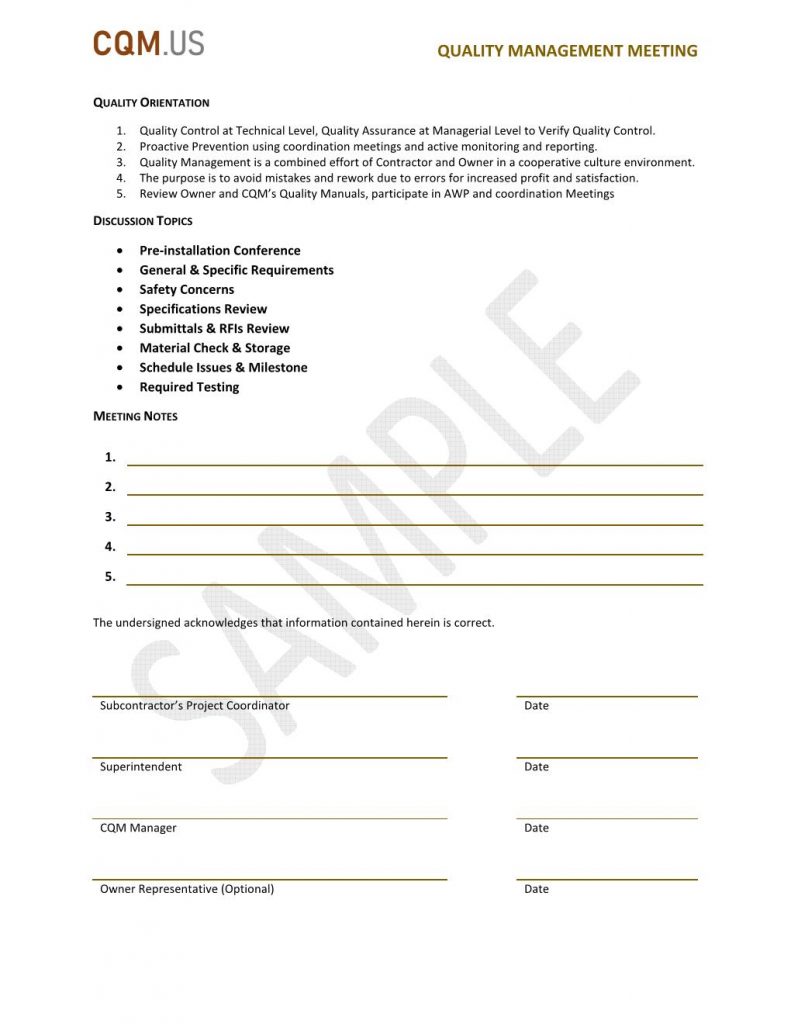

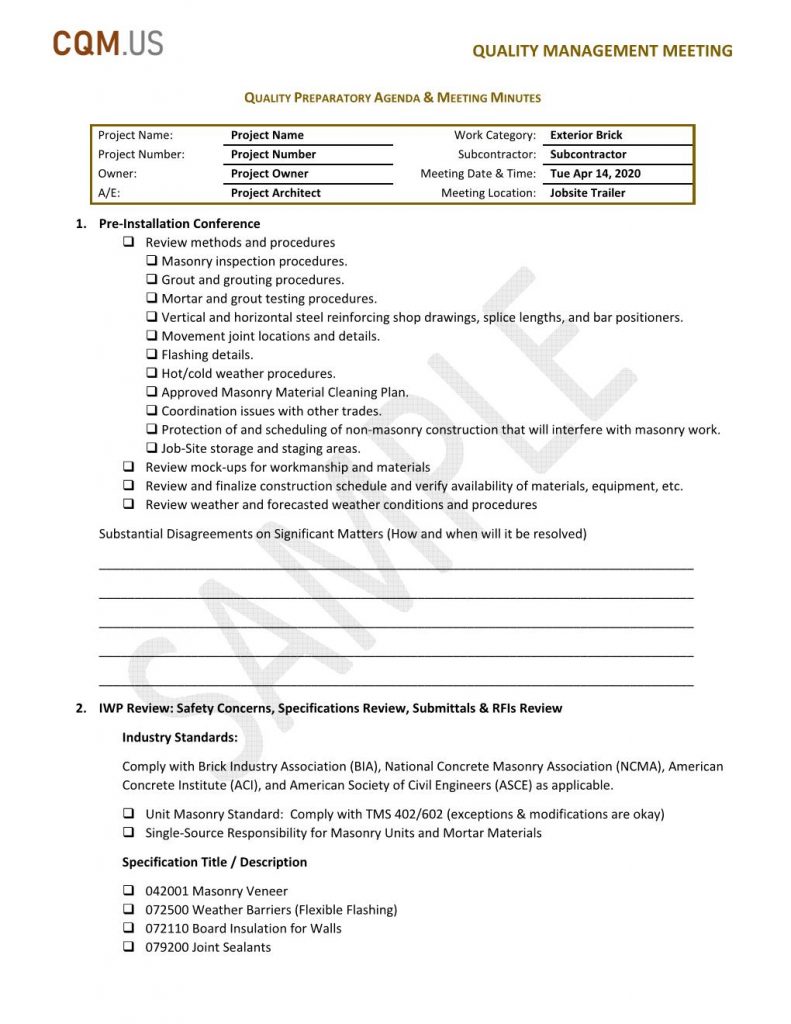

Quality Preparatory Agenda

Since most of the information for the Quality Preparatory Meeting is collected during the IWP package preparation, the Quality Preparatory Agenda is a formal checkpoint to review, verify and confirm all stakeholder’s understanding prior to the beginning of DFoW. Therefore, the most important part of this section is to prepare a summary of all items in an Agenda form with checklist boxes and leave blank spaces for comments, and use the same form as the meeting minute as it is being conducted and obtain signatures from attendees at the end of the meeting.

Therefore, the Meeting Minute is the typed up Quality Preparatory Agenda Form with handwritten checkmarks and additional comment notes. There should be no major disagreement or discussions in this meeting, as issues must have been resolved in previous Kick-off Meeting, IWP Preparation Meetings, BIM Meetings, Scheduling Coordination Meetings, and Request For Information Process! Any new information or requirements that do not match contract documents and approved changes must go through the formal Change Management Process.

There will be no changes made to the contract nor the specifications on the part of the Quality Management Team. The purpose of this meeting is to discuss the Subcontractor’s Quality Plan and Readiness to coordinate what is needed and expected to perform the work required of this Work Category.

CQM Manager’s Disclaimer on CQM Quality Preparatory Agenda

CQM Quality Preparatory

The CQM Quality Preparatory Process satisfies the USCAE CQM-C requirements as well as any A/E preinstallation conferences such as Pre-Concrete or Pre-roofing conferences.

The CQM Quality Preparatory Process will include the following Quality Control and Assurance review and verifications that will be performed by CQM Manager ahead of the meeting and kept for the record the minutes of the meeting.

- Review CQM Orientation main points

- Review SCM contract requirements

- Review Site-Specific and Superintendent’s requirements

- Check Scope of the IWP Packages, Confirm Scope Changes

- Review hazard analysis and Safety Requirements

- Check Schedule and Constraints, Deliveries, and Milestones

- Verify coordinations made with other related SCM Contracts

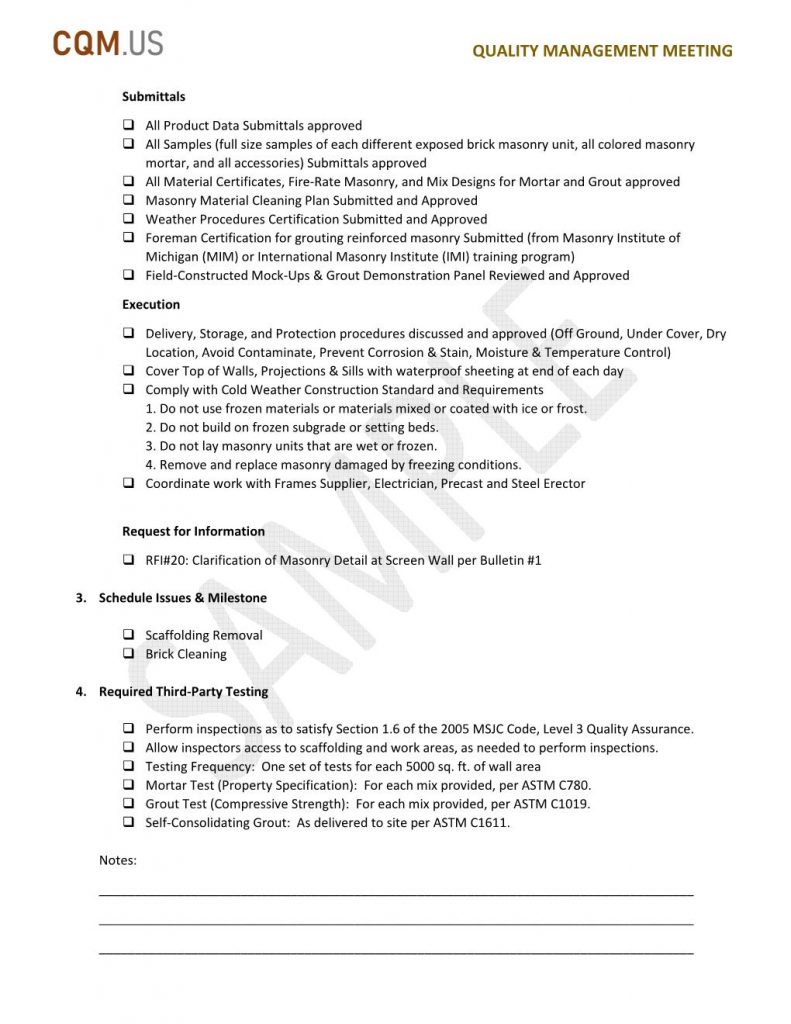

- Verify all related Submittals are approved and review A/E Comments

- Verify all related RFIs are responded and SCM is fully aware of A/E requirements

- Review Specification Requirements with SCM and other Stakeholders

- Review and Confirm Industry Standards to be used are available on-site Library for Field personnel to use

- Review the SCM Quality Manual and Quality Control Checklists

- Review the Established level of workmanship as specified by A/E and Industry’s standards

- Review weather condition impacts Hot/Cold Provisions and SCM Plan and Procedure for weather protection

- Review any Sample Panels, Mock-ups, or Prototypes

- Review Designs, Shop drawings, Mix-Designs, Factory Test Results

- Confirm all materials and/or equipment are on hand, delivery, off-loading, storage, and protection considerations

- Review provisions made to provide required 3rd party control testing procedures and frequencies

- Confirm that the condition of preceding work under other contracts is verified and accepted to start new work

- Confirm understanding of the PMIS System to upload QA/QC related documentation and CQM Manager’s auditing procedures

Quality Management Team ’s reviews do not relieve the Sub-contractor from compliance with the Contract Documents or necessary corrections for deficiencies thereof.

CQM Manager’s Disclaimer on CQM Quality Preparatory Meeting Minutes

All this seems to be overwhelming for the CQM Manager to handle. It must be kept in mind that the CQM Methodology promotes the integration of quality in all Construction Project Management Professional Processes, therefore, many of the above activities are already performed as part of other meetings and the Quality Preparatory Process is the final Checkpoint to confirm all stakeholders are on the same page.

A sample of complete CQM Quality Preparatory Process documentation for brick installation can be found here: